Kia Stinger CK: Engine Control System / ETC (Electronic Throttle Control) System

Specifications

| Specification |

[Throttle Position Sensor (TPS)]

|

Throttle Angle(°) |

Output Voltage(V) [Ref=5V] |

|

|

TPS1 |

TPS2 |

|

|

0 |

0.0 |

5.0 |

|

10 |

0.48 |

4.52 |

|

20 |

0.95 |

4.05 |

|

30 |

1.43 |

3.57 |

|

40 |

1.90 |

3.10 |

|

50 |

2.38 |

2.62 |

|

60 |

2.86 |

2.14 |

|

70 |

3.33 |

1.67 |

|

80 |

3.81 |

1.19 |

|

90 |

4.29 |

0.71 |

|

100 |

4.76 |

0.24 |

|

105 |

5.0 |

0 |

|

C.T (6 - 15°) |

0.29 - 0.71 |

4.29 - 4.71 |

|

W.O.T (93 - 102°) |

4.43 - 4.86 |

0.14 - 0.57 |

[ETC Motor]

|

Item |

Specification |

|

Coil Resistance (Ω) |

1.1 - 1.7 [20°C(68°F)] |

Description and operation

| Description |

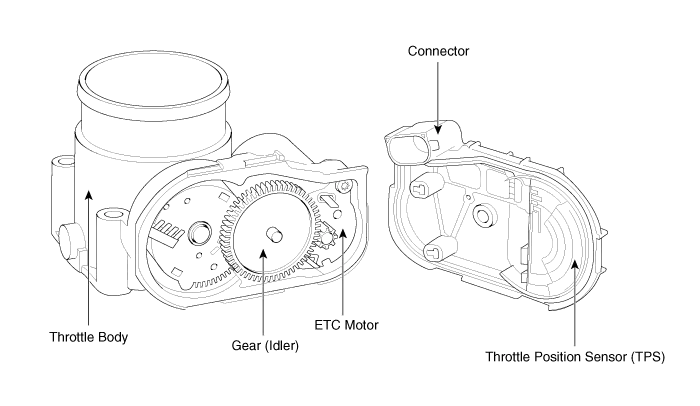

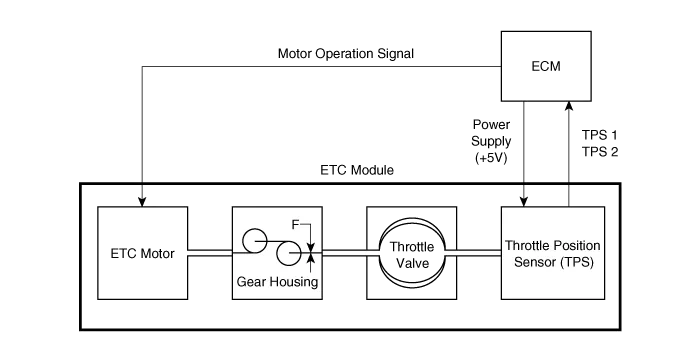

The Electronic Throttle Control (ETC) System consists of a throttle body with an integrated control motor and throttle position sensor (TPS). Unlike the existing mechanical throttle system that controls the throttle valve by using wire cable connected to the accelerator pedal, the ETC system controls the opening and closing of the throttle valve by the ECM with ETC motor according to the APS (Accelerator Position Sensor) signal mounted to electronic accelerator pedal module. The TPS signal is used to provide feedback regarding throttle position to the ECM. Also, the ETC system has the benefit of implementing cruise control function without additional external cruise control modules/cables.

| Schematic Diagram |

Schematic diagrams

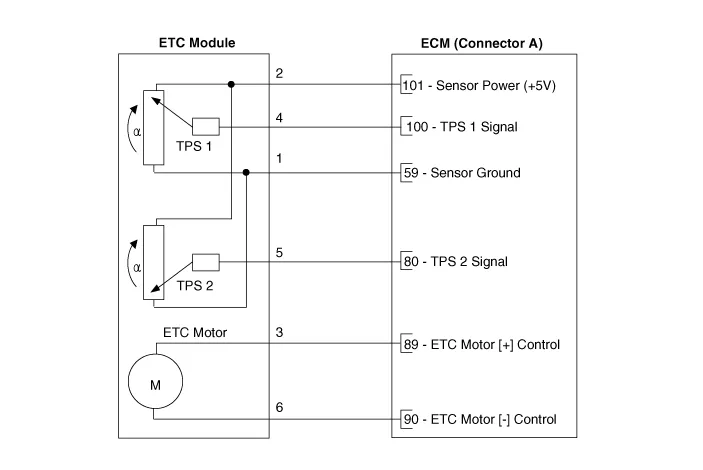

| Circuit Diagram |

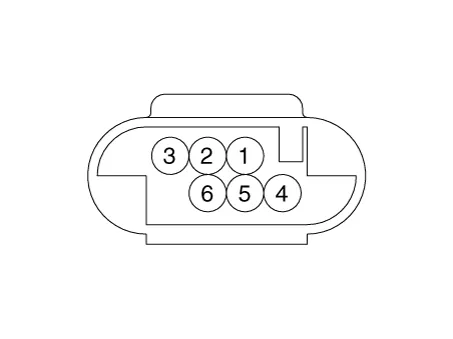

Harness Connector

Repair procedures

| Inspection |

Throttle Position Sensor (TPS)

| 1. |

Connect the KDS on the Data Link Connector (DLC). |

| 2. |

Start the engine and measure the output voltage of TPS 1 and 2 at C.T. and W.O.T.

|

|||||||||||||||||||||||||||||||||||||||||||||||

ETC Motor

| 1. |

Switch "OFF" the ignition. |

| 2. |

Disconnect the ETC module connector. |

| 3. |

Measure resistance between the ETC module terminals 3 and 6. |

| 4. |

Check that the resistance is within the specification.

|

| Removal |

| 1. |

Switch "OFF" the ignition and disconnect the negative (-) battery terminal. |

| 2. |

Remove the alternator assembly. (Refer to Engine Electrical System - "Alternator") |

| 3. |

Remove the intercooler outlet hose & pipe. (Refer to Engine Mechanical System - "Intercooler") |

| 4. |

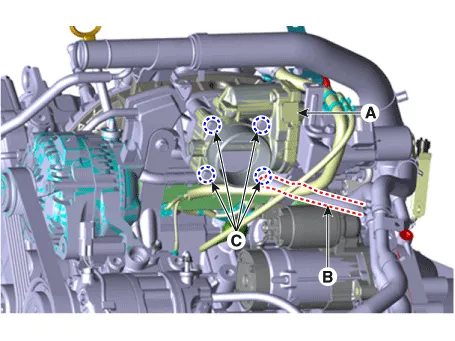

Disconnect the ETC module connector (A). |

| 5. |

Disconnect the coolant hose (B). |

| 6. |

Remove the ETC module from the engine after loosening the installation bolt (C).

|

| Cleaning |

| 1. |

Remove the ETC Module. (Refer to Engine Control System - "ETC System") |

| 2. |

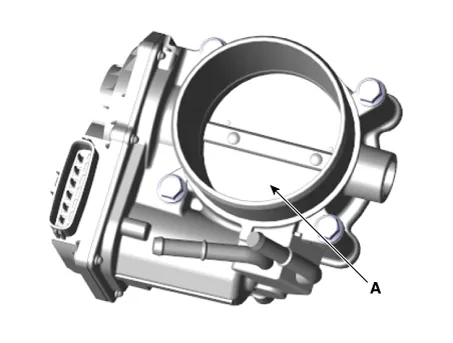

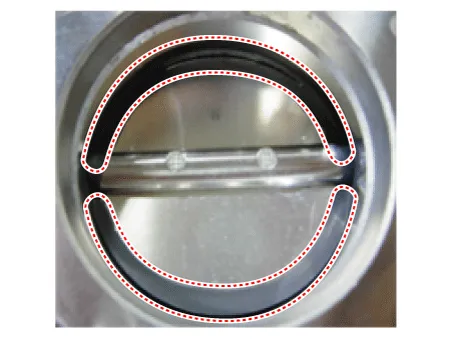

Keep the ETC module plate (A) open.

|

| 3. |

Clean the pollutant in the throttle body with a soft cloth moistened by cleaning fluid.

|

| 4. |

After cleaning, reinstall the ETC module and then perform the ETC module learning procedure. (Refer to Engine Control System - "ETC System" - Adjustment) |

| Installation |

|

| 1. |

Install in the reverse order of removal. |

| Adjustment |

| ETC module learning procedure |

Be sure to perform the ETC module learning procedure when replacing or reinstalling the ETC module.

| 1. |

Wait for 1 minute with the ignition switch ON. |

| 2. |

Start the engine and hold the idle status for 15 minutes. |

| 3. |

Wait for 1 minute with the ignition switch OFF. |

| 4. |

Restart the engine, and check that the idle speed is stable.

|

Troubleshooting

| Fail-Safe Mode |

|

Item |

Fail-Safe |

|

|

ETC Motor |

Throttle valve stuck at 5° |

|

|

TPS |

TPS 1 fault |

ECM looks at TPS2 |

|

TPS 2 fault |

ECM looks at TPS1 |

|

|

TPS 1, 2 fault |

Throttle valve stuck at 5° |

|

|

APS |

APS 1 fault |

ECM looks at APS 2 |

|

APS 2 fault |

ECM looks at APS 1 |

|

|

APS 1, 2 fault |

Throttle valve stuck at 5° |

|

When throttle value is stuck at 7°, engine speed will be limited to below 1,500 rpm and vehicle speed to maximum of 40 - 50 km/h (25 - 31 mph). |

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: 7. Uniform tire quality grading

Quality grades can be found where applicable on the tire sidewall between tread shoulder and maximum section width. For example: TREADWEAR 440 TRACTION A TEMPERATURE A Tread wear The tread wear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a specified government test course. For example, a tire graded 150 would wear one-and-ahalf times (1½) as well on the government course as a tire graded 100.Service data Specifications Description Specifications Limit General Type In-line, DOHC Number of cylinders 4 Bore 86 mm (3.385 in.) Stroke 86 mm (3.Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- New on site

- Most important about car