Kia Stinger CK: What to do in an emergency / Towing

Contents:

Towing service ➤

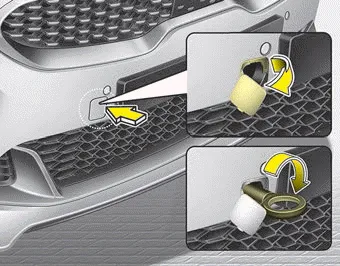

Removable towing hook

1. Open the liftgate, and remove the towing hook from the tool case.

2. Remove the hole cover pressing the right side part or lower part of the cover on the bumper.

3. Install the towing hook by turning it clockwise into the hole until it is fully secured.

4. Remove the towing hook and install the cover after use.

Emergency towing ➤

Other information:

Kia Stinger (CK) 2018-2023 Owner's Manual: If the engine overheats

If your temperature gauge indicates overheating, you experience a loss of power, or hear loud pinging or knocking, the engine will probably be too hot. If this happens, you should: 1.Pull off the road and stop as soon as it is safe to do so. 2.Place the shift lever in P and set the parking brake. If the air conditioning is on, turn it off. 3.Components and components location Components 1. Oil cooler tube 2. Oil cooler pipe 3. Oil cooler valve 4. Oil cooler Repair procedures Replacement Oil cooler 1. Remove the front bumper. (Refer to Body - "Front Bumper Aseembly") 2. Remove the air intake shield (A).Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- New on site

- Most important about car

Contents

Copyright © 2025 www.kstinger.com 0.0099