Kia Stinger CK: Automatic Transmission Control System / Transmission Oil Temperature Sensor

Specifications

| Specifications |

|

Item |

Specification |

|

|

Oil temperature sensor |

Type |

*NTC thermistor |

|

Temp.[(°C)°F] / Resistance (kΩ) |

(-40)-40 / 139.5 |

|

|

(-20)-4 / 47.4 |

||

|

(0)32 / 18.6 |

||

|

(20)68 / 8.1 |

||

|

(40)104 / 3.8 |

||

|

(60)140 / 1.98 |

||

|

(80)176 / 1.08 |

||

|

(100)212 / 0.63 |

||

|

(120)248 / 0.38 |

||

|

(140)284 / 0.25 |

||

|

(150)302 / 0.16 |

||

*NTC: Negative Temperature Coefficient

Components and components location

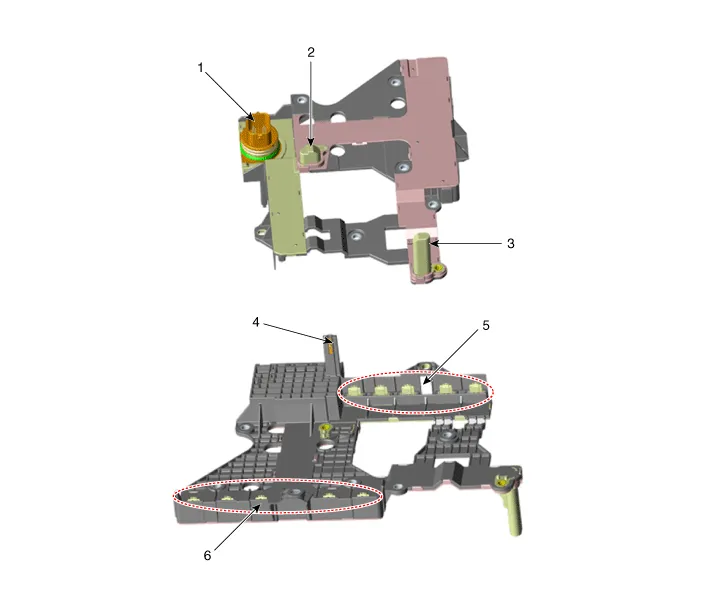

| Components |

| 1. E module connector 2. Output speed sensor 3. Input speed sensor |

4. Oil temperature sensor 5. Indirect control solenoid valve connector 6. Direct control solenoid valve connector |

Description and operation

| Description |

| • |

The sensor used is a thermistor (NTC) in which resistance changes with temperature variation. |

| • |

When the TCM supplies power to sensor, the sensor output value changes depending on ATF temperature. |

| • |

Oil temperature sensor is integrated with E module. |

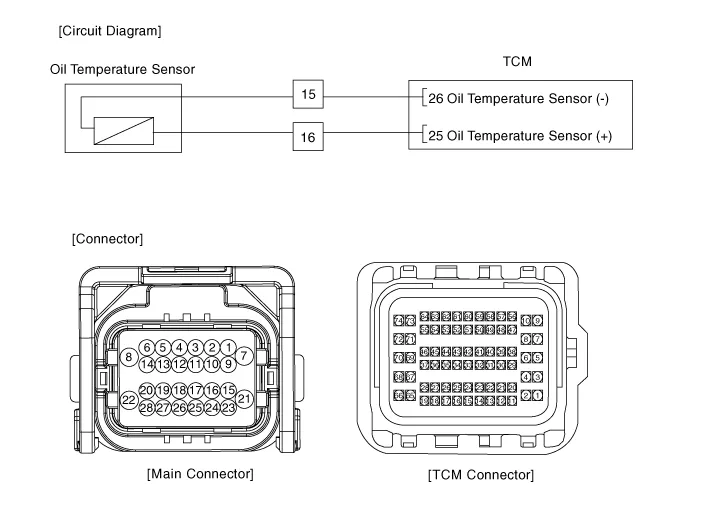

Schematic diagrams

| Circuit Diagram |

Repair procedures

| Inspection |

| 1. |

Switch "OFF" ignition. |

| 2. |

Disconnect the main connector (A).

|

| 3. |

Measure the resistance between + terminal (15) and - terminal (16). |

| 4. |

Check that the resistance is within the specification.

|

||||||||||||||||||

| Replacement |

The oil temperature sensor is integrated into the E-module that can’t be disassembled. So refer to “E-module” for the removal or installation procedure of the oil temperature sensor. |

| 1. |

Replace the E-module. (Refer to Automatic Transmission Control System - "E-Module") |

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: Front Strut Assembly

Components and components location Components 1. Shock absorber 2. Spring lower pad 3. Coil spring 4. Dust cover 5. Bumper stopper 6. Spring upper cover 7. Strut bearing 8. Insulator assembly 9. Lock nut Repair procedures Removal [2WD] 1. Remove wheel nuts, front wheel and tire (A) from hub.Repair procedures Replacement 1. Remove the crankshaft damper pulley. (Refer to Drive Belt System - "Crankshaft Damper Pulley") 2. Remove the front oil seal (A). 3. Install the new front oil seal. (1) Apply engine oil on the edge of new front oil seal.Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- New on site

- Most important about car