Kia Stinger CK: Engine Control System / Heated Oxygen Sensor (HO2S)

Specifications

| Specification |

HO2S [Bank 1/Sensor 1]

|

Item |

Specification |

|

Heater Resistance (Ω) |

2.5 - 4.0 [20°C(68°F)] |

HO2S [Bank 1/Sensor 2]

|

Item |

Specification |

|

Heater Resistance (Ω) |

3.3 - 4.1 [20°C(69.8°F)] |

Description and operation

| Description |

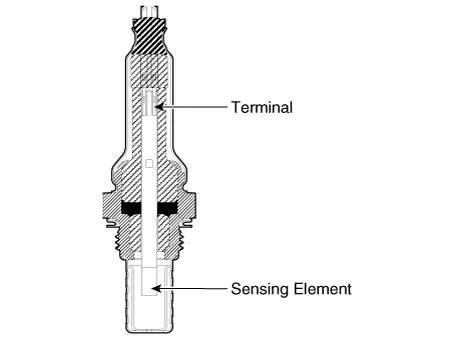

Heated Oxygen Sensor (HO2S), consisting of zirconium and alumina, is installed on both upstream and downstream of the Catalytic Converter to detect the air/fuel ratio and send it to the ECM.

The sensor must be heated in order to operate properly. To keep it heated, the sensor has a heater which is controlled by the ECM via a duty cycle signal. When the exhaust gas temperature is lower than the specified value, the heater warms up the sensor tip.

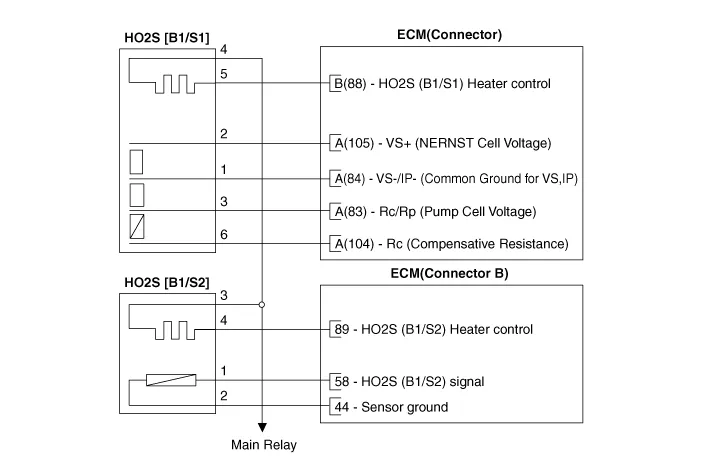

Schematic diagrams

| Circuit Diagram |

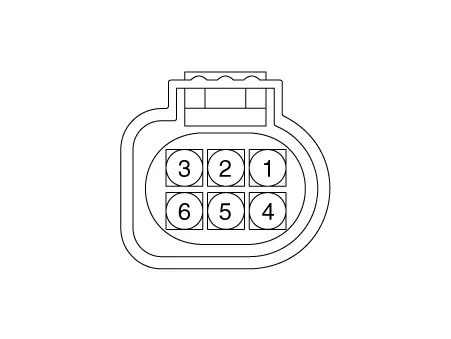

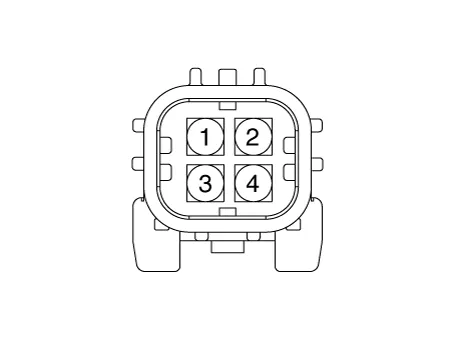

Harness Connector

[Bank 1 / Sensor 1]

[Bank 1 / Sensor 2]

Repair procedures

| Inspection |

| 1. |

Switch "OFF" the ignition. |

| 2. |

Disconnect the HO2S connector. |

| 3. |

Measure resistance between the HO2S terminals 4 and 5 [B1/S1].

|

| 4. |

Measure resistance between the HO2S terminals 3 and 4 [B1/S2].

|

| 5. |

Check that the resistance is within the specification. |

| Removal |

Note that the SST (Part No. : 09392-1Y100 or 09392-2H100) is useful when removing the heated oxygen sensor. |

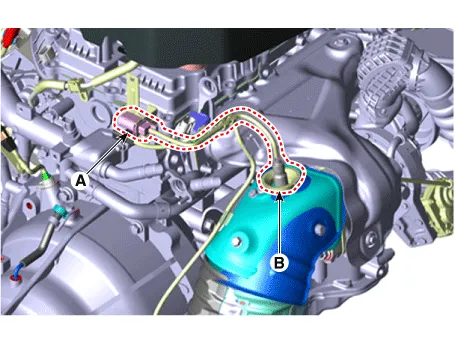

[Bank 1 / Sensor 1]

| 1. |

Switch "OFF" the ignition and disconnect the negative (-) battery terminal. |

| 2. |

Disconnect the connector (A), and then remove the sensor (B).

|

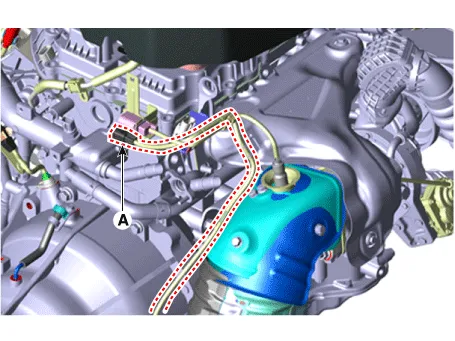

[Bank 1 / Sensor 2]

| 1. |

Switch "OFF" the ignition and disconnect the negative (-) battery terminal. |

| 2. |

Disconnect the connector (A).

|

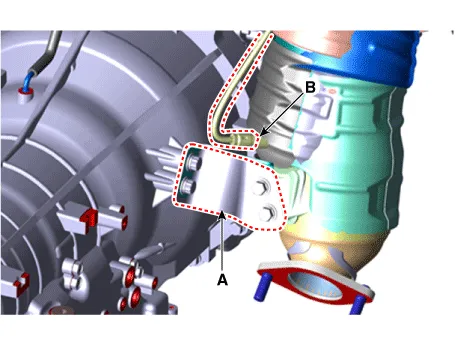

| 3. |

Lift the vehicle. |

| 4. |

Remove the catalytic converter bracket (A). |

| 5. |

Remove the sensor (B).

|

| Installation |

|

| 1. |

Install in the reverse order of removal.

|

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: Keep your vehicle clean

The best way to prevent corrosion is to keep your vehicle clean and free of corrosive materials. Attention to the underside of the vehicle is particularly important. If you live in a high-corrosion area — where road salts are used, near the ocean, areas with industrial pollution, acid rain, etc.—, you should take extra care to prevent corrosion.Kia Stinger (CK) 2018-2023 Service Manual: Automatic Transmission Control System

Description and operation Description Automatic transmission control system relies on various measurements to determine the current control status and determine the necessary compensation values. These values are used to control the actuators and achieve the desired control output. Control System Composition Shift By Wire (SBW) System Composition ▶ Operating Principle – Instead of cable, the system uses electronic signals to shift between the P-R-N-D gears.Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- New on site

- Most important about car