Kia Stinger CK: Engine Control / Fuel System / Specifications

Service data

| Service Data |

| Fuel Delivery System |

|

Items |

Specification |

|

|

Fuel Tank |

Capacity |

60 L (15.8 U.S.gal., 63.4 U.S.qt., 52.7 Imp.qt.) |

|

Fuel Filter |

Type |

Paper type |

|

Fuel Pressure |

Low Pressure Fuel Line |

Over 290 kPa (Over 2.9 bar, Over 2.95 kgf/cm², Over 42.06 psi) |

|

High Pressure Fuel Line |

2.0 - 20 MPa (20.4 - 203 kgf/cm², 290.1 - 2900 psi) |

|

|

Fuel Pump |

Type |

Electrical, in-tank type |

|

Driven by |

Electric motor |

|

|

High Pressure Fuel Pump |

Type |

Mechanical type |

|

Driven by |

Camshaft |

|

| Fuel pump motor |

|

Item |

Specification |

||

|

Output Voltage (V) |

12.6 |

||

|

Low Pressure Fuel Line |

bar |

3.5 - 6.0 |

|

|

kPa |

350 - 600 |

||

|

kgf/cm² |

3.5 - 6.1 |

||

|

psi |

50.7 - 87.0 |

||

| Fuel sender |

[Main Fuel Sender]

|

Position |

Resistance (Ω) |

Capacity (ℓ) |

|

E |

148 - 152 |

4.5 |

| 1/2

|

6.5 - 8.5 |

31.2 |

|

F |

6.5 - 8.5 |

58.5 |

[Sub Fuel Sender]

|

Position |

Resistance (Ω) |

Capacity (ℓ) |

|

E |

148 - 152 |

4.5 |

| 1/2

|

148 - 152 |

31.2 |

|

F |

6.5 - 8.5 |

58.5 |

[Main Fuel Sender + Sub Fuel Sender Composite resistance]

|

Position |

Resistance (Ω) |

Capacity (ℓ) |

|

E |

296 - 304 |

4.5 |

| 1/2

|

154.5 - 160.5 |

31.2 |

|

F |

13 - 17 |

58.5 |

| Sensors |

Manifold Absolute Pressure Sensor (MAPS)

▷ Type: Piezo-resistive pressure sensor type

▷ Specification

|

Item |

Specification |

|

Output Voltage (V) |

5 |

|

Pressure (KPa) |

32.5 - 284 |

|

Operating Voltage (V) |

4.5 - 5.5 |

|

Pressure [kPa (kgf/cm², psi)] |

Output Voltage (Vref = 5V) |

|

32.5 (0.33, 4.71) |

0.5 |

|

70 (0.71, 10.1) |

1.1 |

|

270 (2.75, 39.1) |

4.3 |

|

284 (2.89, 41.1) |

4.5 |

Boost Pressure Sensor (BPS)

▷ Type: Piezo-resistive pressure sensor type

▷ Specification

|

Item |

Specification |

|

Output Voltage (V) |

5 |

|

Pressure (KPa) |

32.5 - 284 |

|

Operating Voltage (V) |

4.5 - 5.5 |

|

Pressure [kPa (kgf/cm², psi)] |

Output Voltage (Vref = 5V) |

|

32.5 (0.33, 4.71) |

0.5 |

|

70 (0.71, 10.1) |

1.1 |

|

270 (2.75, 39.1) |

4.3 |

|

284 (2.89, 41.1) |

4.5 |

Intake Air Temperature Sensor (IATS)

▷ Type: Thermistor type

▷ Specification

|

Temperature |

Resistance (kΩ) |

|

|

°C |

°F |

|

|

-40 |

-40 |

40.93 - 48.35 |

|

-20 |

-4 |

13.89 - 16.03 |

|

0 |

32 |

5.38 - 6.09 |

|

10 |

50 |

3.48 - 3.90 |

|

20 |

68 |

2.31 - 2.57 |

|

40 |

104 |

1.08 - 1.21 |

|

50 |

122 |

1.56 - 1.74 |

|

60 |

7140 |

0.54 - 0.62 |

|

80 |

176 |

0.29 - 0.34 |

Ambient Temperature Sensor (ATS)

▷ Specification

|

Temperature[⁰C(⁰F)] |

Resistance(kΩ) |

|

-40(-40) |

811.1 - 956.8 |

|

-20(-4) |

255.6 - 287.7 |

|

0(32) |

91.5 - 98.8 |

|

20(68) |

36.6 - 38.0 |

|

30(86) |

23.8 - 24.7 |

|

40(104) |

15.7 - 16.6 |

|

50(122) |

10.6 - 11.3 |

|

60(140) |

7.2 - 7.9 |

|

80(176) |

3.6 - 4.0 |

Engine Coolant Temperature Sensor (ECTS)

▷ Type: Thermistor type

▷ Specification

|

Temperature |

Resistance (kΩ) |

|

|

°C |

°F |

|

|

-40 |

-40 |

48.14 |

|

-20 |

-4 |

14.13 - 16.83 |

|

0 |

32 |

5.79 |

|

20 |

68 |

2.31 - 2.59 |

|

40 |

104 |

1.15 |

|

60 |

140 |

0.59 |

|

80 |

176 |

0.32 |

Throttle Position Sensor (TPS) [integrated into ETC Module]

▷ Type: Variable resistor type

▷ Specification

|

Throttle Angle(°) |

Output Voltage (V) [Vref = 5V] |

|

|

TPS1 |

TPS2 |

|

|

0 |

0 |

5.0 |

|

10 |

0.48 |

4.52 |

|

20 |

0.95 |

4.05 |

|

30 |

1.43 |

3.57 |

|

40 |

1.90 |

3.10 |

|

50 |

2.38 |

2.62 |

|

60 |

2.86 |

2.14 |

|

70 |

3.33 |

1.67 |

|

80 |

3.81 |

1.19 |

|

90 |

4.29 |

0.71 |

|

100 |

4.76 |

0.24 |

|

105 |

5.0 |

0 |

|

C.T (6-15°) |

0.29 - 0.71 |

4.29 - 4.71 |

|

W.O.T (93-102°) |

4.43 - 4.86 |

0.14 - 0.57 |

Crankshaft Position Sensor (CKPS)

▷ Type: Hall effect type

|

Item |

Specification |

|

Type |

Magnetic field sensitive |

|

Output Voltage (V) |

4.75 - 5.25 (25°C) |

|

Input Voltage (V) |

0.6 - 4.5 |

|

Air Cap (mm) |

0.5 - 1.5 |

Camshaft Position Sensor (CMPS)

▷ Type: Hall effect type

|

Item |

Specification |

|

Air Cap (mm) |

0.2 - 2.0 |

Knock Sensor (KS)

▷ Type: Piezo-electric type

▷ Specification

|

Item |

Specification |

|

Capacitance (pF) |

850 - 1,150 |

|

Resistance (MΩ) |

Approx. 1 |

Heated Oxygen Sensor (HO2S) [Bank 1/Sensor 1]

▷ Type: Zirconia (ZrO2) [Linear] Type

▷ Specification

|

Item |

Specification |

|

Heater Resistance (Ω) |

2.5 - 4.0 [20°C(69.8°F)] |

Heated Oxygen Sensor (HO2S) [Bank 1/Sensor 2]

▷ Type: Zirconia (ZrO2) [Binary] Type

▷ Specification

|

Item |

Specification |

|

Heater Resistance (Ω) |

3.3 - 4.1 [20°C(69.8°F)] |

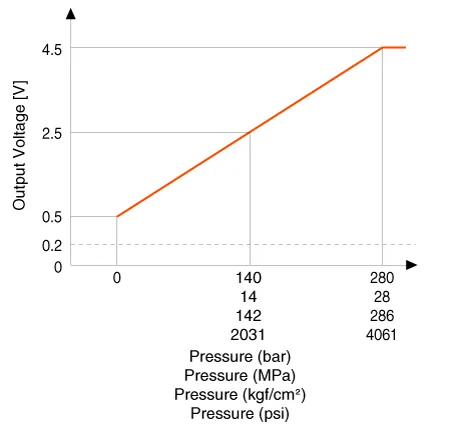

Rail Pressure Sensor (RPS)

▷ Type: Piezo-electric type

▷ Specification

|

Pressure |

Output Voltage (V) [Vref=5V] |

|

|

bar |

[MPa (kgf/cm², psi)] |

|

|

0 |

0 (0, 0) |

0.5 |

|

140 |

14 (142, 2031) |

2.5 |

|

280 |

28 (286, 4061) |

4.5 |

CVVT Oil Temperature Sensor (OTS)

▷ Type: Thermistor type

▷ Specification

|

Temperature [°C (°F)] |

Resistance (kΩ) |

|

-40 |

52.15 |

|

-20 |

28.82 |

|

0 |

14.08 - 19.45 |

|

20 |

2.16 - 2.78 |

|

40 |

1.11 |

|

60 |

0.54 |

|

80 |

0.26 - 0.32 |

|

100 |

0.16 |

|

120 |

0.1 |

|

140 |

0.06 |

Accelerator Position Sensor (APS)

▷ Type: Variable resistor type

▷ Specification

|

Accelerator Position |

Output Voltage (V) [Vref = 5V] |

|

|

APS1 |

APS2 |

|

|

C.T |

0.7 - 0.8 |

0.33 - 0.43 |

|

W.O.T |

3.99 - 4.23 |

1.94 - 2.18 |

| Actuators |

ETC Motor [integrated into ETC Module]

▷ Specification

|

Item |

Specification |

|

Coil Resistance (Ω) |

1.1 - 1.7 [20°C(68°F)] |

Injector

▷ Specification

|

Item |

Specification |

|

Coil Resistance (Ω) |

1.4 - 1.6 [20°C(68°F)] |

Purge Control Solenoid Valve (PCSV)

▷ Specification

|

Item |

Specification |

|

Coil Resistance (Ω) |

18.5 - 22.5 [20°C(68°F)] |

CVVT Oil Control Valve (OCV) [Bank 1 / Exhaust]

▷ Specification

|

Item |

Specification |

|

Coil Resistance (Ω) |

6.9 - 7.9 [20°C(68°F)] |

Fuel Pressure Control Valve (FPCV)

▷ Specification

|

Item |

Specification |

|

Coil Resistance (Ω) |

0.47 - 0.53 [20°C(68°F)] |

RCV Control Solenoid Valve

▷ Specification

|

Item |

Specification |

|

Coil Resistance (Ω) |

28.3 - 31.1 [20°C(68°F)] |

Variable Charge Motion Actuator (VCMA)

▷ Specification

|

Item |

Specification |

|

Coil Resistance (Ω) |

18.5 - 22.5 [20°C(68°F)] |

E-CVVT Motor [Bank 1 / Intake]

▷ Specification

|

Item |

Specification |

|

Operation angle |

90° |

|

Initial postion |

Completely Advance (When starting, it can be adjusted) |

|

Gear ratio |

60:01:00 |

|

Motor Max. power |

140W / 12V |

|

Current |

Max. 35A [-30 °C] / 1A [When maintaining the phase] |

| Fuel Delivery System Item |

Fuel Pump Motor

▷ Specification

|

Item |

Specification |

|

Normal state |

Operate |

Fuel sender

▷ Specification

|

Position |

Resistance (Ω) |

|

E |

297 - 303 |

| 1/2

|

80 - 84 |

|

F |

14 - 16 |

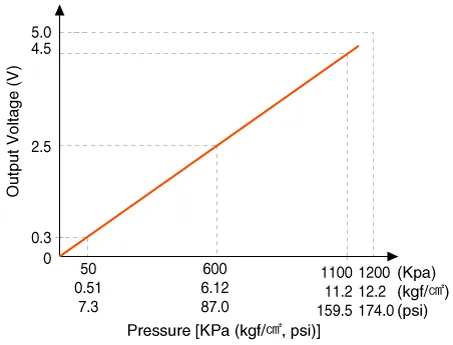

Fuel Pressure Sensor (FPS)

▷ Specification

|

Pressure [KPa (kgf/cm², psi)] |

Output Voltage (V) [Vref = 5V] |

|

50 (0.51, 7.3) |

0.3 |

|

600 (6.12, 87.0) |

2.5 |

|

1100 (11.2, 159.5) |

4.5 |

| Service Standard |

|

Item |

Specification |

||

|

Ignition Timing (°) |

BTDC 6 ± 10 |

||

|

Idle Speed (rpm) |

A/C OFF |

Neutral, N, P-range |

640 ± 100 |

|

D-range |

600 ± 100 |

||

|

A/C ON |

Neutral, N, P-range |

660 ± 100 |

|

|

D-range |

660 ± 100 |

||

Tightening torque

| Tightening Torques |

Engine Control System

|

Item |

kgf·m |

N·m |

lb·ft |

|

ECM bracket mounting bolt/ nut |

1.0 - 1.2 |

9.8 - 11.8 |

7.2 - 8.7 |

|

Electronic Throttle Control (ETC) Module mounting bolt |

1.0 - 1.2 |

9.8 - 11.8 |

7.2 - 8.7 |

|

Manifold Absolute Pressure Sensor (MAPS) mounting bolt |

1.0 - 1.2 |

9.8 - 11.8 |

7.2 - 8.7 |

|

Intake Air Temperature Sensor (IATS) mounting bolt |

1.0 - 1.2 |

9.8 - 11.8 |

7.2 - 8.7 |

|

Boost Pressure Sensor (BPS) mounting bolt |

1.0 - 1.2 |

9.8 - 11.8 |

7.2 - 8.7 |

|

Crankshaft position sensor (CKPS) mounting bolt |

1.0 - 1.2 |

9.8 - 11.8 |

7.2 - 8.7 |

|

Camshaft position sensor (CMPS) [Bank 1 / Intake] mounting bolt |

1.0 - 1.2 |

9.8 - 11.8 |

7.2 - 8.7 |

|

Camshaft position sensor (CMPS) [Bank 1 / Exhaust] mounting bolt |

1.0 - 1.2 |

9.8 - 11.8 |

7.2 - 8.7 |

|

Knock Sensor (KS) mounting bolt |

1.9 - 2.4 |

18.6 - 23.5 |

13.7 - 17.4 |

|

Heated oxygen sensor (HO2S) [Bank 1 / sensor 1] |

4.0 - 5.0 |

39.2 - 49.1 |

28.9 - 36.2 |

|

Heated oxygen sensor (HO2S) [Bank 1 / sensor 2] |

4.0 - 5.0 |

39.2 - 49.1 |

28.9 - 36.2 |

|

Rail Pressure Sensor (RPS) |

1.8 - 2.2 |

18.0 - 22.0 |

13.3 - 16.2 |

|

Accelerator pedal module mounting bolt/nut |

0.9 - 1.4 |

8.8 - 13.7 |

6.5 - 10.1 |

|

CVVT Oil Control Valve (OCV) [Bank 1 / Exhaust] mounting bolt |

1.0 - 1.2 |

9.8 - 11.8 |

7.2 - 8.7 |

|

Variable Charge Motion Actuator (VCMA) mounting bolt |

1.0 - 1.4 |

9.8 - 11.8 |

7.2 - 8.7 |

|

Oil Temperature Sensor (OTS) |

3.5 - 4.5 |

34.3 -44.1 |

25.3 - 32.5 |

|

RCV Control Solenoid Valve |

1.0 - 1.2 |

9.8 - 11.8 |

7.2 - 8.7 |

Fuel Delivery System

|

Item |

kgf·m |

N·m |

lb·ft |

|

Fuel tank band mounting nut |

4.0 - 5.5 |

39.2 - 54.0 |

28.9 - 39.8 |

|

High pressure fuel pipe mounting nut |

2.7 - 3.3 |

26.5 - 32.4 |

19.5 - 23.9 |

|

High pressure fuel pipe function block mounting bolt |

0.8 - 1.2 |

7.8 - 11.8 |

5.8 - 8.7 |

|

Filler-neck assembly bracket mounting bolt |

0.4 - 0.6 |

3.9 - 5.9 |

2.9 - 4.3 |

|

Delivery pipe mounting bolt |

1.9 - 2.4 |

18.6 - 23.5 |

13.7 - 17.4 |

|

High pressure fuel pump mounting bolt |

1.3 - 1.5 |

12.8 - 14.7 |

9.4 - 10.9 |

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: Sub Frame

Repair procedures Removal [2WD] 1. Remove wheel nuts, front wheel and tire (A) from hub. Tightening torque: 107.9 - 127.5 N·m (11.0 - 13.0 kgf·m, 79.6 - 94.0 lb·ft) Be careful not to damage the wheel bolts when removing the wheel and tire (A).Kia Stinger (CK) 2018-2023 Service Manual: Fuse/relay panel description

■ Driver’s side fuse panel ■ Engine compartment fuse panel ■ Rear fuse box panel ■ Battery box fuse panel Inside the fuse/relay panel covers, you can find the fuse/relay label describing fuse/relay name and capacity. ✽ NOTICE Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing.Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- New on site

- Most important about car