Kia Stinger CK: Engine Mechanical System / Cooling System

Kia Stinger (CK) 2018-2023 Service Manual / Engine Mechanical System / Cooling System

Contents:

- Coolant

- Cooling Fan

- Radiator

- Reservoir Tank

- Water Temperature Control Assembly

- Electric Thermostat (ECT)

- Water pump

Components and components location

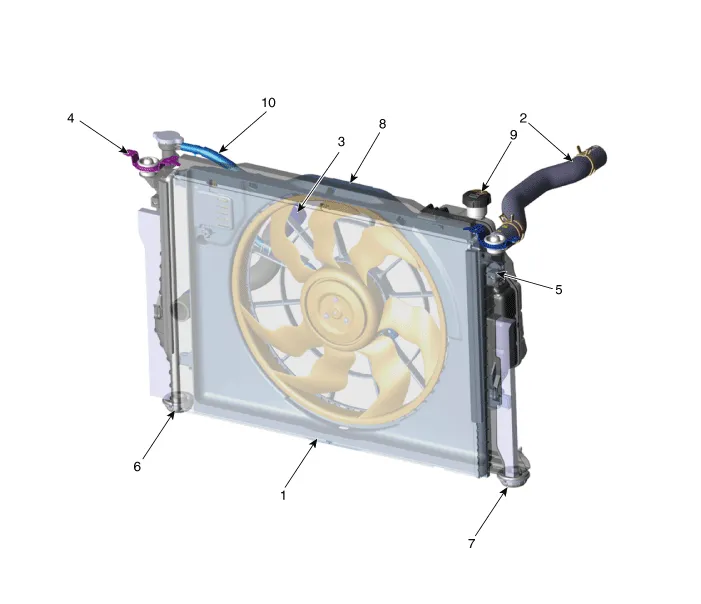

| Components |

| 1. Radiator 2. Radiator upper hose 3. Radiator lower hose 4. Radiator upper mounting bracket (RH) 5. Radiator upper mounting bracket (LH) |

6. Radiator lower mounting insulator

(RH) 7. Radiator lower mounting insulator (LH) 8. Cooling fan assembly 9. Reservoir tank 10. Reservoir hose |

Troubleshooting

| Engine Overheat Troubleshooting |

|

Inspection |

Remedy |

||||||||

|

Visual inspection |

Inspect for shortage of coolant in reservoir tank . |

Reinspect after replenishing coolant. |

|||||||

Inspect for coolant pollution after removing radiator cap.

|

Reinspect after replacing coolant. |

||||||||

|

Inspect for leakage and loose coolant hoses (radiator hose, heater hose,

oil cooler hose, etc.). |

Reinspect for leakage after reinstalling hoses and clamps. |

||||||||

|

Inspect for leakage on water inlet fitting mounting part. |

Reinspect for leakage after replacing O-ring. |

||||||||

|

Reinspect for leakage after tightening to the specified torque. |

|||||||||

|

Inspect drive belt (for normal operation of water pump). |

Adjust drive belt tension or replace. |

||||||||

|

Inspect for leakage on water pump gasket mounting part. |

Reinspect for leakage after replacing gasket. |

||||||||

|

Reinspect for leakage after tightening to the specified torque. |

|||||||||

|

Inspect for loose coolant temperature sensor, cooling fan connector and

pin. |

Reinstall loose connector. |

||||||||

|

Replace relevant part if connector pin is damaged. |

|||||||||

|

Inspect operation status of cooling fan. - Check operation status by switching ON/OFF the heater control A/C.

|

Check mounting status of ground cable. |

||||||||

|

Diagnostic device |

Inspect self-diagnostic code using KDS/GDS. |

Check coolant temperature sensor, wiring, connector, etc. |

|||||||

|

Unit inspection |

Inspect water pump impeller. |

Replace water pump. |

|||||||

|

Inspect for foreign materials and status of thermostat valve. |

Inspect unit after removing foreign materials. |

||||||||

|

Inspect for stuck thermostat valve. - Immerse thermostat in water heated to over 95°C (203°F), then heat for at least 3 minutes to check valve lift.

|

Check valve lift. - Replace thermostat if valve lift is below specification or valve is stuck. |

||||||||

Coolant ➤

Cooling Fan ➤

Radiator ➤

Reservoir Tank

Repair procedures

| Removal |

| 1. |

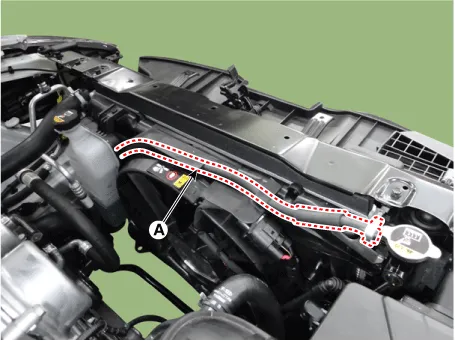

Disconnect the reservoir hose (A).

|

| 2. |

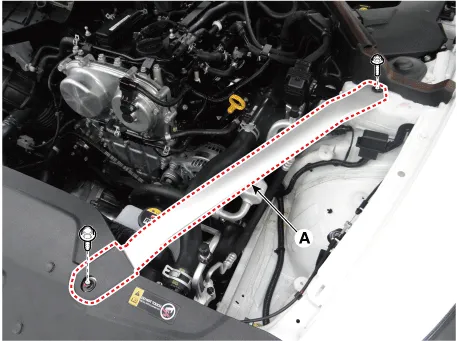

Remove the LH front strut bar (A).

|

| 3. |

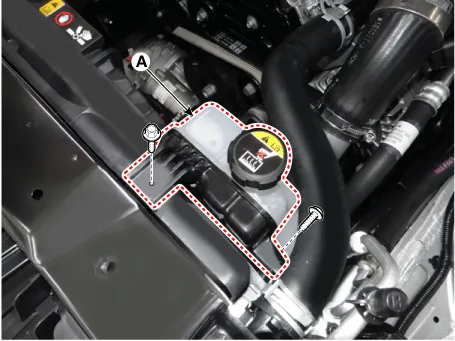

Remove the reservoir tank (A).

|

| 4. |

Install in the reverse order of removal. |

Water Temperature Control Assembly ➤

Electric Thermostat (ECT) ➤

Water pump ➤

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: Heater Control Unit

Description and operation Description Smart Ventilation It is a system that actively ventilates when the humidity inside the passenger compartment increases with the air conditioning OFF. 1. Entry condition a. Air conditioning OFF b. When humidity rises c.1. Park on a level surface and apply the parking brake firmly. 2. Place the transaxle shift lever in P (Park). 3. Activate the hazard warning flashers. 4. Remove the wheel lug nut wrench, jack and spare tire from the vehicle. 5. Block both the front and rear of the wheel that is diagonally opposite from the jack position. WARNING - Jack location To reduce the possibility of injury, be sure to use only the jack provided with the vehicle in the correct jack position; never use any other part of the vehicle for jack support.Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- Coolant

- Cooling Fan

- Radiator

- Reservoir Tank

- Water Temperature Control Assembly

- Electric Thermostat (ECT)

- Water pump

- New on site

- Most important about car

Contents

Copyright © 2026 www.kstinger.com 0.0128