Symptoms

|

Possible Causes

|

Remedy

|

Coolant leakage

|

| • |

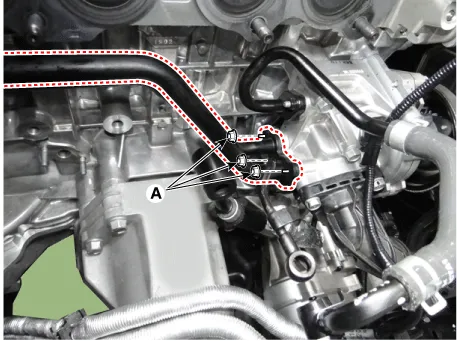

From the bleed hole of the water pump

|

|

Visually check

|

| • |

Check leaks after about ten-minute warming up.

|

|

| • |

If coolant still leaks, replace a water pump.

|

|

| • |

If leakage stops, reuse the water pump (Do not replace the pump

with a new one).

|

|

|

|

| • |

Check the tightening of the water pump mounting bolts.

|

|

| • |

Retighten the mounting bolts.

|

|

| • |

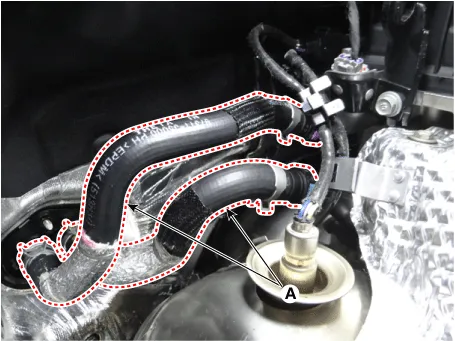

Check damage of gaskets or inflow of dust.

|

|

| • |

Replace the gasket and clean dust off.

|

|

| • |

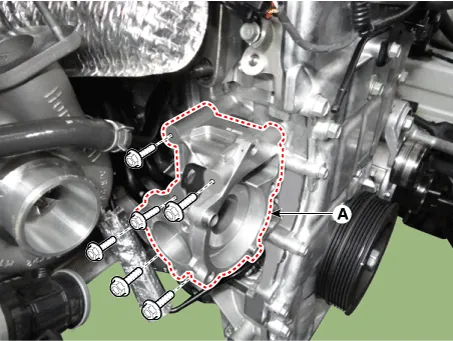

From outer surface of water pump

|

|

| • |

Check the material or any cracks of the water pump.

|

|

| • |

Poor material. If any crack found, replace the water pump.

|

|

Noise

|

|

Inspection with a stethoscope

|

| • |

After starting the engine, check noise with a stethoscope.

|

|

| • |

If there is no noise, reuse the water pump(do not replace it).

|

|

| • |

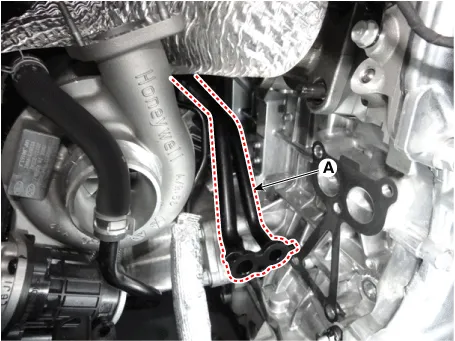

If there is any noise from the water pump, remove the drive belt

and recheck.

|

|

Inspection after removing a drive belt

|

| • |

After removing a water pump and a drive belt, check noise again.

|

|

| • |

If there is noise, reuse the water pump. Check other drive line

parts.

|

|

| • |

If there is no noise, replace the water pump with a new one.

|

|

Inspection after removing a water pump

|

| • |

After removing a water pump and a drive belt, check noise again.

|

|

| • |

If there is any interference between them, replace the water

pump with a new one.

|

|

Overheating

|

|

Loosened impeller

|

| • |

Corrosion of the impeller wing

|

|

| • |

Poor coolant quality / Maintenance check

|

|

| • |

Impeller seperation from the shaft

|

|

| • |

Replace the water pump.

|

|

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: Transmission ranges

The indicator in the instrument cluster displays the shift lever position when

the engine start/stop button is in the ON position.

However, if the gear is in N (Neutral) or P (Park), the position is displayed

on the instrument cluster when the engine start/stop button is in the OFF or ACC

position.

CAUTION - Transmission

To avoid damage to your transmission, do not accelerate the engine in R (Reverse)

or any forward gear position with the brakes on.

Kia Stinger (CK) 2018-2023 Service Manual: Front Lower Arm

Repair procedures

Removal

[2WD Lateral arm]

1.

Remove wheel nuts, front wheel and tire (A) from hub.

Tightening torque:

107.9 - 127.5 N·m (11.0 - 13.0 kgf·m, 79.6 - 94.0 lb·ft)

Be careful not to damage the wheel bolts when removing the wheel

and tire (A).