Kia Stinger CK: Drive Belt System / Drive Belt

Repair procedures

| Removal |

| 1. |

Remove the engine room front under cover. (Refer to Engine and Transmission Assembly - "Engine Room Under Cover") |

| 2. |

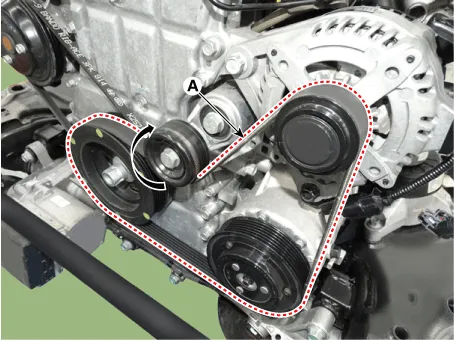

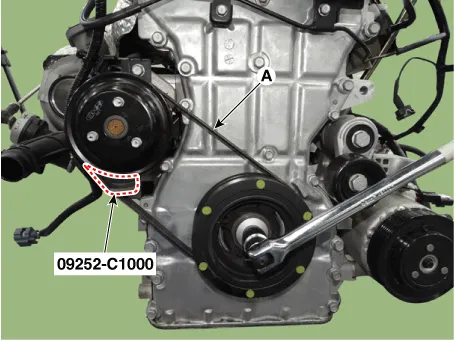

For release the tension, turn the drive belt tensioner (A) counterclockwise then remove the drive belt (B).

|

| 3. |

Remove the water pump belt.

|

| Inspection |

| 1. |

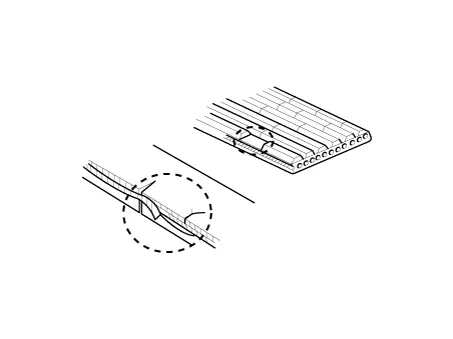

Visually check the belt for excessive wear, frayed cords etc. If any defect has been found, replace the drive belt.

|

| Installation |

| 1. |

Install the water pump belt.

|

| 2. |

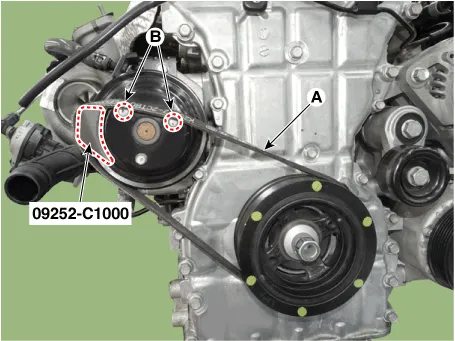

For release the tension, turn the drive belt tensioner (A) counterclockwise then install the drive belt (B).

|

| 3. |

Install the other parts in the reverse order of removal. |

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: Roof Trim Assembly

Components and components location Component Location 1. Roof Trim Assembly Repair procedures Replacement Put on gloves to protect your hands. • Use a plastic panel removal tool to remove interior trim pieces without marring the surface.Repair procedures Inspection 1. Connect the battery voltage and check for blower motor operation. 2. If the blower motor does not operate well, substitute with a known-good blower motor and check for proper operation. 3. Replace the blower motor if it is proved that there is a problem with it.Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- New on site

- Most important about car