Kia Stinger CK: Front Driveshaft Assembly / Front Driveshaft

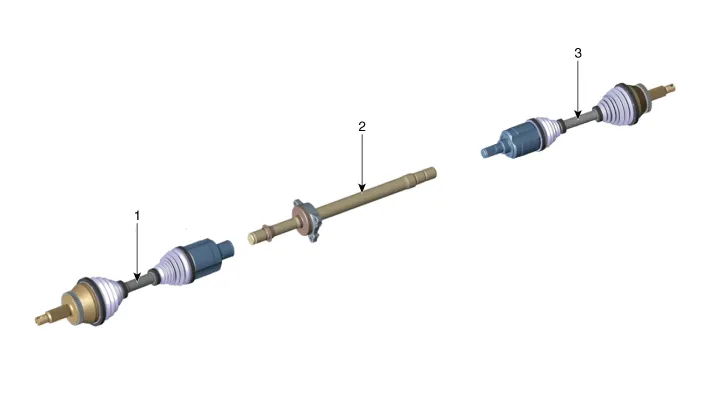

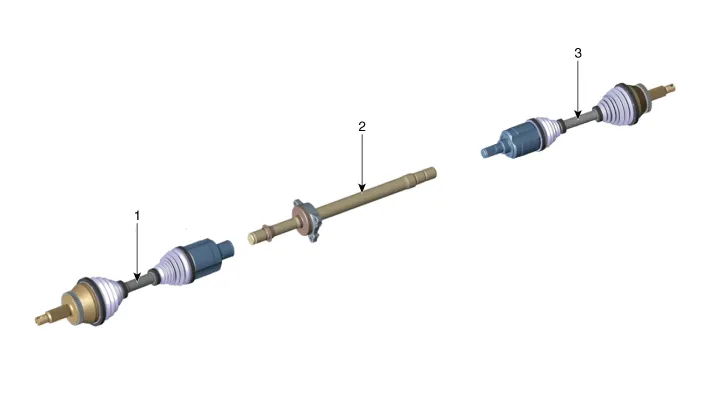

Components and components location

1. Front drive shaft [LH]

2. Front drive shaft bracket

|

3. Front drive shaft [RH]

|

Repair procedures

[3.3 T-GDI LAMBDA II

(LH)]

| 1. |

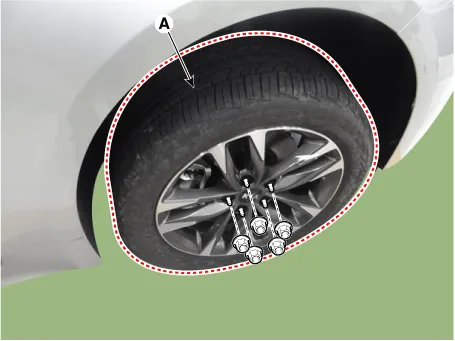

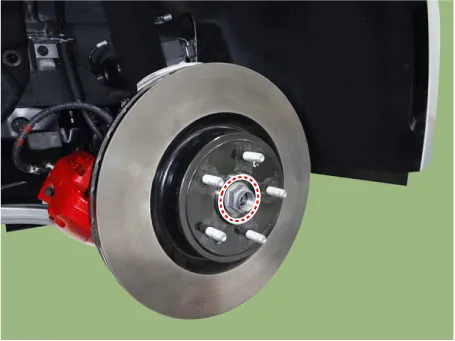

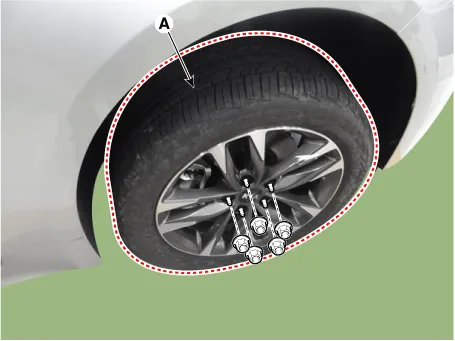

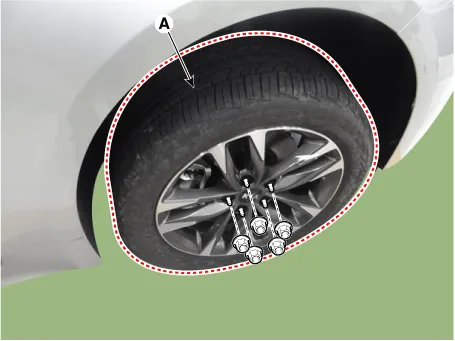

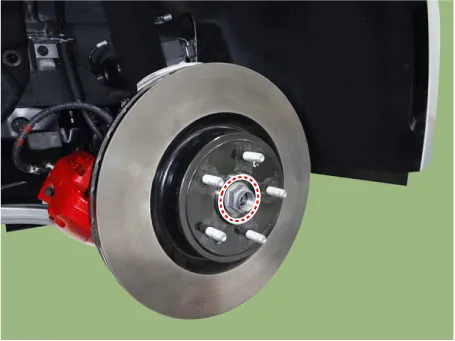

Remove wheel nuts, front wheel and tire (A) from front hub.

|

Tightening torque:

107.9 - 127.5 N·m (11.0 - 13.0 kgf·m, 79.6 - 94.0 lb·ft)

|

|

Be careful not to damage the wheel nuts when removing the front

wheel and tire (A).

|

|

| 2. |

Separate the air con compressor.

(Refer to Heating,Ventilation And Air Conditioning - "Compressor")

|

| 3. |

Remove the front brake caliper.

(Refer to Brake System - "Front Disc Brake")

|

| 4. |

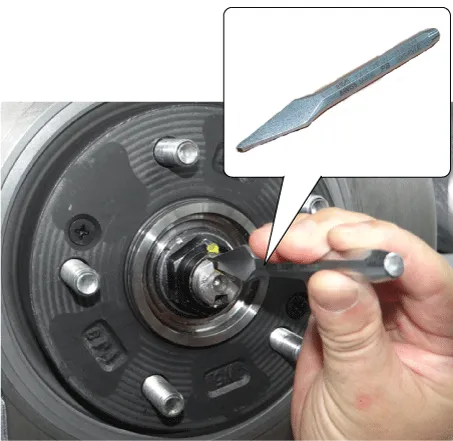

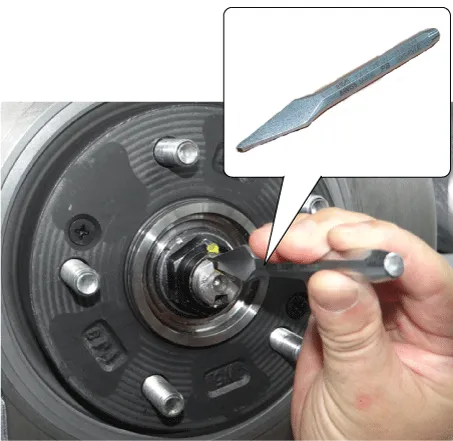

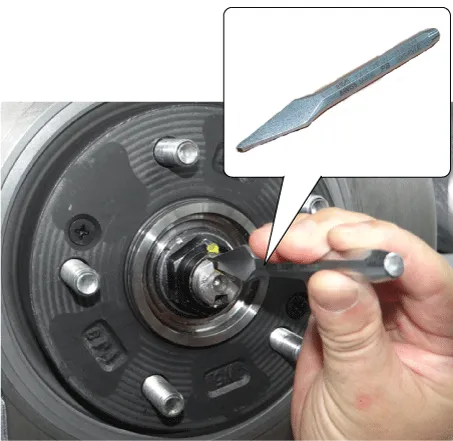

By hammering on a chisel, unlock the drive shaft lock hub nut caulking.

|

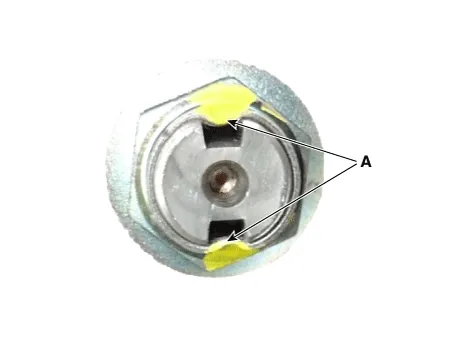

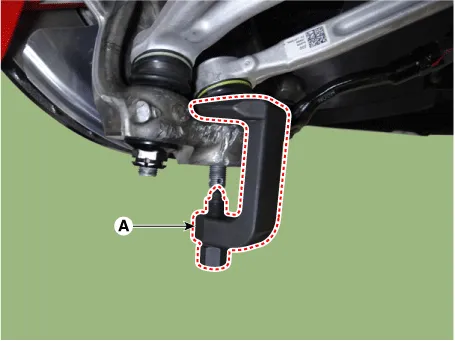

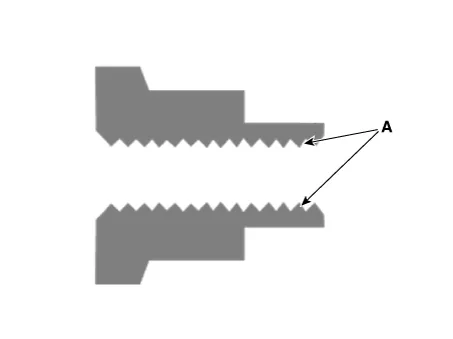

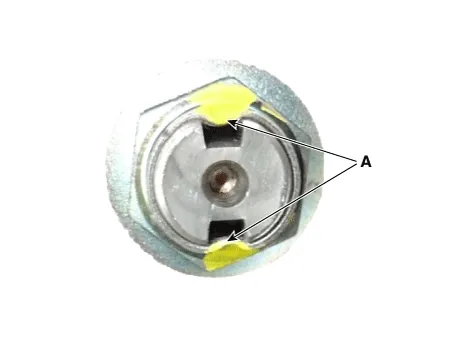

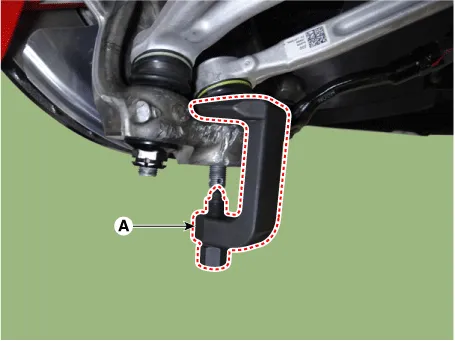

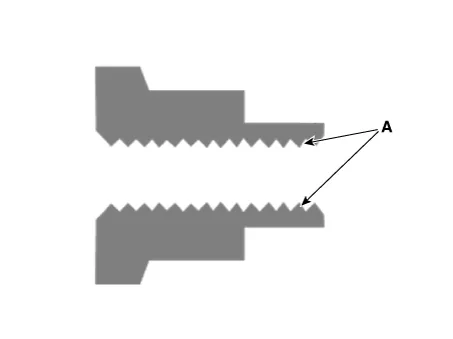

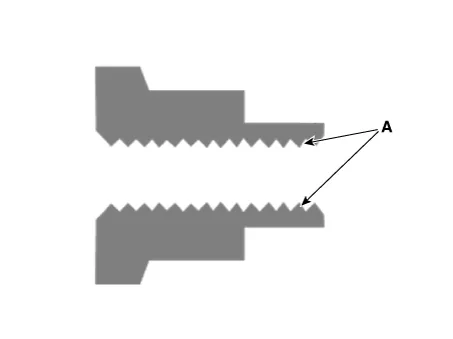

If there is screw thread (A) on the end of the nut, unlock the

caulking by using a chisel and then loosen the nut to prevent damaging

driveshaft screw thread.

|

|

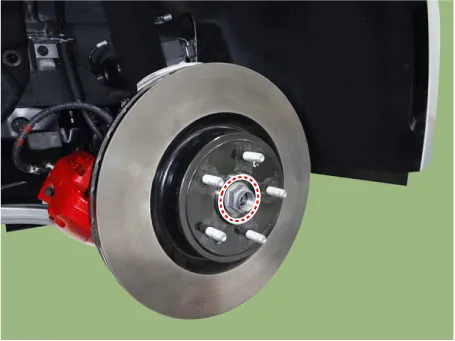

| 5. |

Loosen the caulking nut and then separate the hub assembly from the drive

shaft.

|

Tightening torque :

294.2 - 313.8 N·m (30.0 - 32.0 kgf·m, 217.0 - 231.5 lb·ft)

|

| •

|

Use plastic hammer to avoid damaging on axle when the

drive shaft is disassembled.

|

| •

|

Do not pull or twist excessively to remove the axle when

the drive shaft is disassembled.

|

|

|

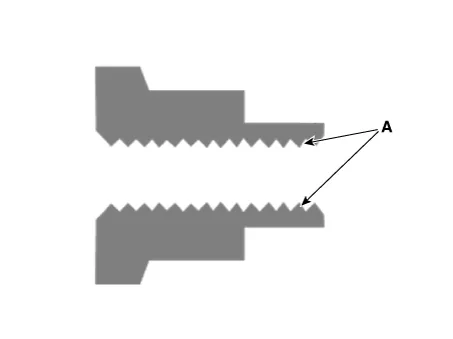

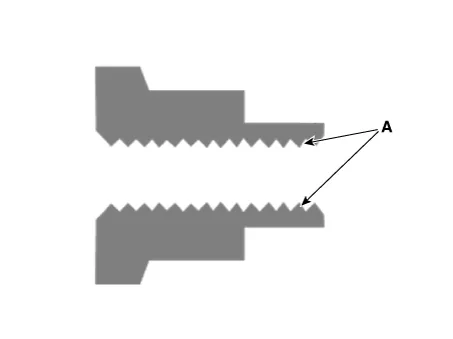

The driveshaft lock nut must be replaced with new one.

When replacing the drive lock hub nut, use only the nut with

screw thread (A) on the end.

| •

|

Tighten the driveshaft lock hub nut to the specified

tightening torque, and caulk by using a chisel and hammer.

|

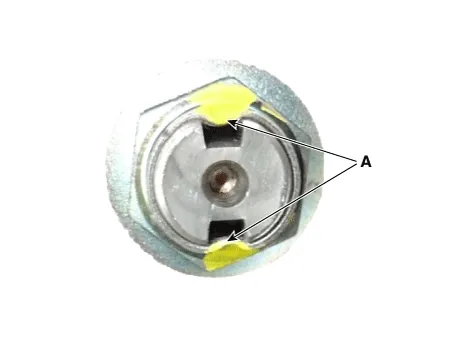

| •

|

If there are two key seats, perform on all two seats.

Caulking depth (A) : 1.5 mm (0.0591 in)

|

|

|

| 6. |

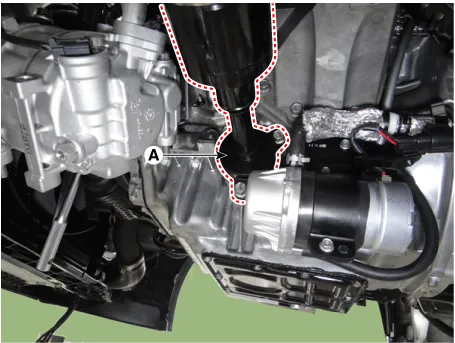

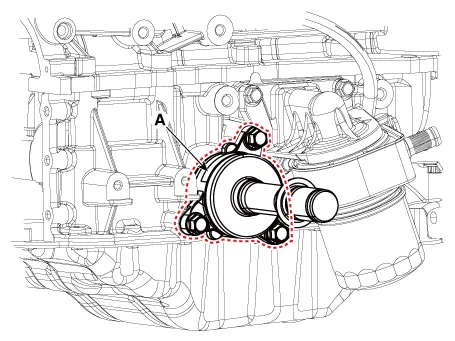

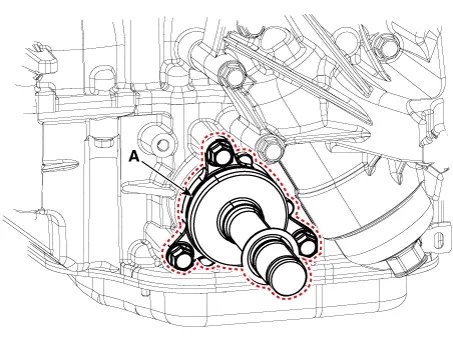

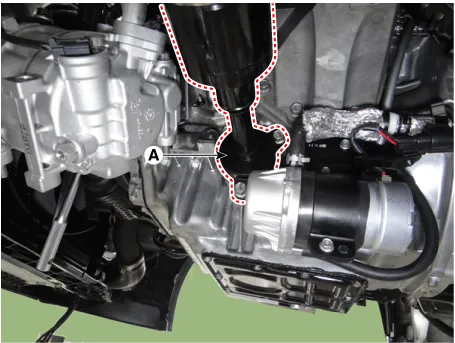

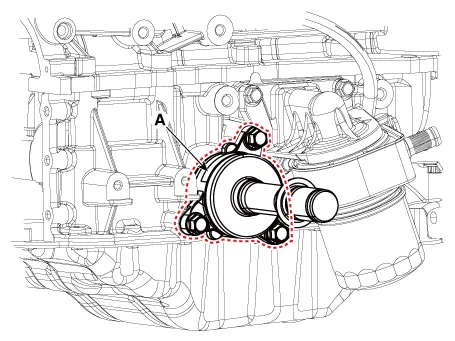

Remove the front drive shaft bracket (A) from the front differential

and then using pry bar, remove the front drive shaft [LH].

|

Tightening torque :

49.0 - 63.7 N·m (5.0 - 6.5 kgf·m, 36.2.0 - 47.0 lb·ft)

|

|

| 7. |

Install in the reverse order of removal.

| •

|

Use a pry bar being careful not to damage the transaxle

and joint.

|

| •

|

Do not insert the pry bar too deep, as this may cause

damage to the oil seal.

|

| •

|

Do not pull the driveshaft by excessive force it may

cause components inside the joint kit to dislodge resulting

in a torn boot or a damaged bearing.

|

| •

|

Plug the hole of the transaxle case with the oil seal

cap to prevent contamination.

|

| •

|

Support the driveshaft properly.

- Be careful that the drive shaft is not bent or drop

down by other component's weight (such as axle etc.)

|

| •

|

Replace the retainer ring whenever the driveshaft is

removed from the transaxle case.

|

|

|

| 8. |

Check the front alignment.

(Refer to Suspension System - "Alignment")

|

[2.0 T-GDI THETA II,

R 2.2(RH,LH)]

[3.3 T-GDI LAMBDA II

(RH)]

| 1. |

Remove wheel nuts, front wheel and tire (A) from front hub.

|

Tightening torque:

107.9 - 127.5 N·m (11.0 - 13.0 kgf·m, 79.6 - 94.0 lb·ft)

|

|

Be careful not to damage the wheel nuts when removing the front

wheel and tire (A).

|

|

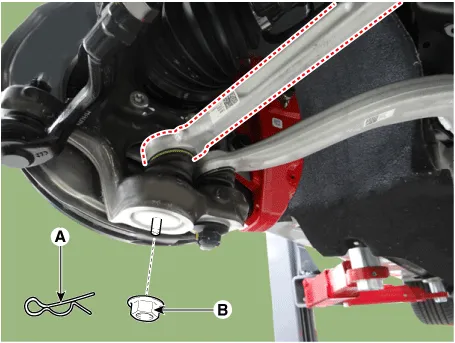

| 2. |

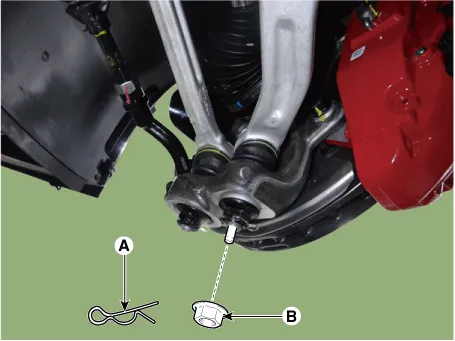

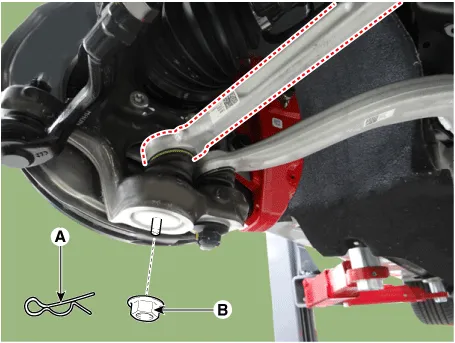

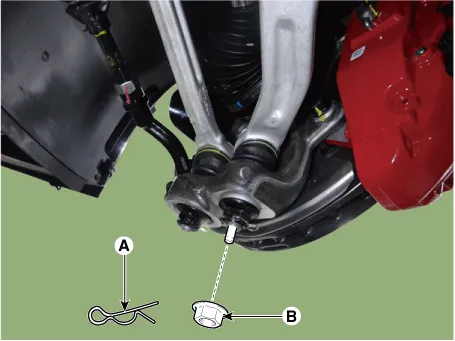

Loosen the lateral arm pin (A) and nut (B).

|

Tightening torque:

88.3 - 107.9 N·m (9.0 - 11.0 kgf·m, 65.1 - 79.6 lb·ft)

|

|

| 3. |

Remove the rateral arm by using the ball joint remover (A).

|

| 4. |

Loosen the compression arm pin (A) and nut (B).

|

Tightening torque :

88.3 - 107.9 N·m (9.0 - 11.0 kgf·m, 65.1 - 79.6 lb·ft)

|

|

| 5. |

Remove the compression arm by using the ball joint remover (A).

|

| 6. |

Loosen the nut and then separate the stabilizer link from the front shock

absorber.

|

Tightening torque :

98.1 - 117.7 N·m (10.0 - 12.0 kgf·m, 72.3 - 86.8 lb·ft)

|

|

| 7. |

By hammering on a chisel, unlock the driveshaft lock hub nut caulking.

|

If there is screw thread (A) on the end of the nut, unlock the

caulking by using a chisel and then loosen the nut to prevent damaging

driveshaft screw thread.

|

|

| 8. |

Loosen the caulking nut and then separate the hub assembly from the drive

shaft.

|

Tightening torque :

294.2 - 313.8 N·m (30.0 - 32.0 kgf·m, 217.0 - 231.5 lb·ft)

|

| •

|

Use plastic hammer to avoid damaging on axle when the

drive shaft is disassembled.

|

| •

|

Do not pull or twist excessively to remove the axle when

the drive shaft is disassembled.

|

|

|

The driveshaft lock nut must be replaced with new one.

When replacing the drive lock hub nut, use only the nut with

screw thread (A) on the end.

| •

|

Tighten the driveshaft lock hub nut to the specified

tightening torque, and caulk by using a chisel and hammer.

|

| •

|

If there are two key seats, perform on all two seats.

Caulking depth (A) : 1.5 mm (0.0591 in)

|

|

|

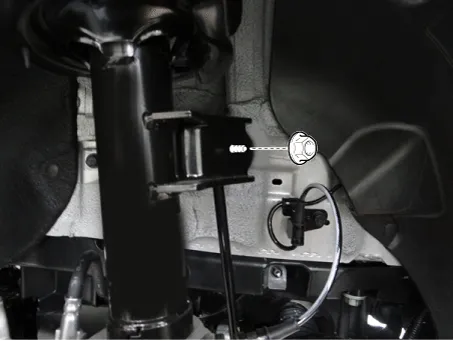

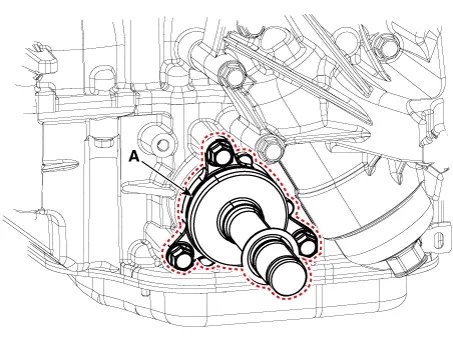

| 9. |

Remove the front drive shaft bracket (A). [LH]

|

Tightening torque :

49.0 - 63.7 N·m (5.0 - 6.5 kgf·m, 36.2.0 - 47.0 lb·ft)

|

[2.0 T-GDI

THETA II]

[R 2.2]

|

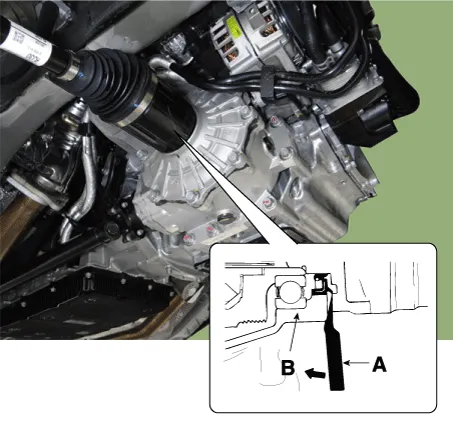

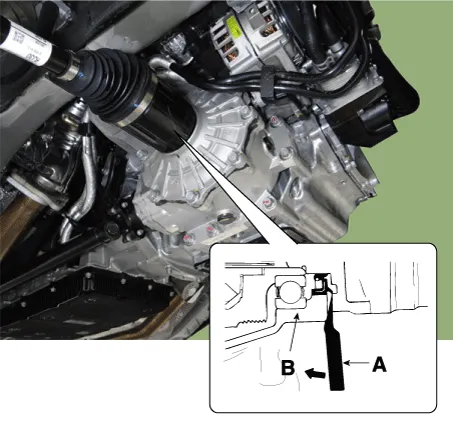

| 10. |

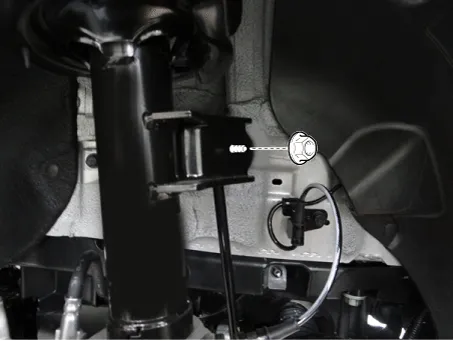

Using pry bar (A), separate the front drive shaft from the front differential

(B).

| •

|

Use a pry bar being careful not to damage the transaxle

and joint.

|

| •

|

Do not insert the pry bar too deep, as this may cause

damage to the oil seal.

|

| •

|

Do not pull the driveshaft by excessive force it may

cause components inside the joint kit to dislodge resulting

in a torn boot or a damaged bearing.

|

| •

|

Plug the hole of the transaxle case with the oil seal

cap to prevent contamination.

|

| •

|

Support the driveshaft properly.

- Be careful that the drive shaft is not bent or drop

down by other component's weight (such as axle etc.)

|

| •

|

Replace the retainer ring whenever the driveshaft is

removed from the transaxle case.

|

|

|

| 11. |

Install in the reverse order of removal.

|

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: Windshield defrosting and defogging

WARNING - Windshield heating

Do not use the

or

position during cooling operation

in extremely humid weather. The difference between the temperature of the outside

air and the windshield could cause the outer surface of the windshield to fog up,

causing loss of visibility. In this case, set the mode selection to the

position and fan speed control to

the lower speed.

Kia Stinger (CK) 2018-2023 Service Manual: System malfunction

When the “Check System” warning message appears, the system is not working properly.

In this case, have the vehicle inspected by an authorized Kia dealer.

WARNING

The Driver Attention Warning system is not a substitute for safe driving

practices. It is the responsibility of the driver to always drive cautiously

to prevent unexpected and sudden situations from occurring.