Kia Stinger CK: Driveshaft and axle

Kia Stinger (CK) 2018-2023 Service Manual / Driveshaft and axle

Contents:

- Specifications

- Front Axle Assembly

- Rear Axle Assembly

- Front Driveshaft Assembly

- Rear Driveshaft Assembly

- Propeller Shaft Assembly

- Differential Carrier Assembly

Special service tools

| Special Service Tools |

|

Tool Name / Number |

Illustration |

Description |

|

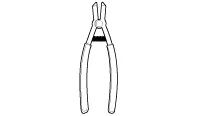

09495-3K000 Band installer |

|

Installation of ear type boot band |

|

09495-39100 Band installer |

|

Installation of hook type boot band |

|

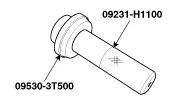

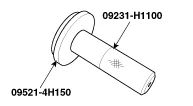

09231-H1100 Bar |

|

|

|

09500-11000 Bar |

|

|

|

09432-3D900 Front differential carrier side bearing race installer |

|

Installation of the side bearing race. (Use with 09231-H1100 ) |

|

09474-4E100 Front differential carrier side oil seal installer |

|

Installation of the differential carrier oil seal installer. (Use with 09231-H1100) |

|

09474-4E200 Front/Rear differential bearing remover |

|

Used for removing differential bearing |

|

09474-4E300 Pinion cage oil seal installer |

|

Installation of pinion cage oil seal. |

|

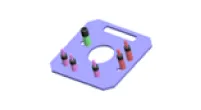

09474-4E400 Front differential assembly working stand |

|

Removal & Installation of the differential assembly working stand. |

|

09474-4E500 Front differential pinion front bearing race installer |

|

Installation of pinion front bearing race. (Use with 09231-H1100) |

|

09432-3D500 Front differential side bearing installer |

|

Installation of the differential carrier side bearing. (Use with (09231-H1100) |

|

09432-33700 Front/Rear differential pinion rear bearing race installer |

|

Installation of the pinion bearing. (Use with 09231-H1100) |

|

09452-1P100 Front differential carrier cover oil seal installer |

|

Installation of differential carrier cover oil seal. (Use with 09231-H1100) |

|

09452-2W300 Front differential side bearing race remover adapter |

|

Removal of differential side bearing race. |

|

0K530-4J100 Rear differential assembly working stand |

|

Removal & Installation of the differential assembly working stand. |

|

0K530-4J200 Rear differential pinion inner bearing race installer |

|

Installation of pinion bearing race. |

|

0K530-4J300 Rear differential bearing installer |

|

Installation of differential bearing. |

|

09530-3T500 Differential side oil seal installer |

|

Installation of the differential side oil seal. (Use with 09231-H1100) |

|

09530-3T600 Differential pinion oil seal installer |

|

Installation of the differential pinion oil seal. |

|

09521-4H150 Rear differential pinion outer bearing race installer |

|

Used for installing drive pinion outer bearing outer race Used with the handle (09231-H1100) |

|

09530-3C200 Rear differential carrier side bearing installer |

|

Installation of the differential bearing. |

|

09453-3B500 Differential case side race installer |

|

Installation of the differential bearing race. (Use with 09231-H1100) |

|

0K517-J5100 |

|

Knuckle expand tool |

Troubleshooting

| Troubleshooting |

|

Trouble Symptom |

Probable cause |

Remedy |

|

Vehicle pulls to one side |

Scoring of driveshaft ball joint |

Replace |

|

Wear, rattle or scoring of wheel bearing |

Replace |

|

|

Defective front suspension and steering |

Adjustment or Replace |

|

|

Vibration |

Wear, damage or bending of driveshaft |

Replace |

|

Driveshaft rattle and hub serration |

Replace |

|

|

Wear, rattle or scratching of wheel bearing |

Replace |

|

|

Shimmy |

Defective wheel balance |

Adjustment or Replace |

|

Defective front suspension and steering |

Adjustment or Replace |

|

|

Excessive noise |

Wear, damage or bending of driveshaft |

Replace |

|

Rattle of driveshaft and worn hub splines |

Replace |

|

|

Wear, rattle or scoring of wheel bearing |

Replace |

|

|

Loose hub nut |

Adjustment or Replace |

|

|

Defective front suspension and steering |

Adjustment or Replace |

Specifications ➤

Front Axle Assembly ➤

Rear Axle Assembly ➤

Front Driveshaft Assembly ➤

Rear Driveshaft Assembly ➤

Propeller Shaft Assembly ➤

Differential Carrier Assembly ➤

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: Fuel Filter (For Diesel engine only)

Repair procedures Removal 1. Switch "OFF" the ignition and disconnect the negative (-) battery terminal. 2. Remove the engine cover (A). 3. Disconnect the water sensor connector & fuel heater connector (A), fuel pressure sensor connector (B). 4.Kia Stinger (CK) 2018-2023 Service Manual: Turbocharger & Exhaust Manifold

Components and components location Components 1. Turbo manifold module 2. Turbo manifold module gasket 3. Heat protector 4. Warm-up catalytic converter (WCC) heat protector 5. Oil feed pipe 6. Turbo manifold module stay 7. Oil drain pipe 8. Turbocharger oil drain pipe gasket A 9.Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- Specifications

- Front Axle Assembly

- Rear Axle Assembly

- Front Driveshaft Assembly

- Rear Driveshaft Assembly

- Propeller Shaft Assembly

- Differential Carrier Assembly

- New on site

- Most important about car

Contents

Copyright © 2026 www.kstinger.com 0.009