Kia Stinger CK: Brake System / Stop Lamp Switch

Components and components location

| Components |

| 1. Brake lamp switch |

2. Brake pedal |

Description and operation

| Operation |

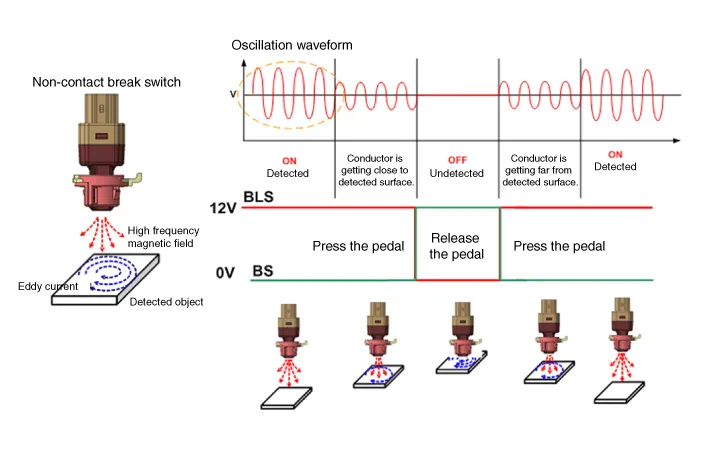

Operation principle of inductive non-contact switch

| 1. |

Use the high frequency magnetic field and the induced current that are generated by oscillation (to approved voltage) of coil in switch. |

| 2. |

The eddy current is generated on surface of metal by self inductance effect if there is metal in high frequency magnetic field. |

| 3. |

The eddy current that is generated attenuates the high frequency magnetic field as much as amount of generated by disturbing the switch's magnetic flux. |

| 4. |

ON-OFF by judging whether high voltage magnetic field is attenuates or not(caluculate the voltage difference by length between metal and coil) |

Schematic diagrams

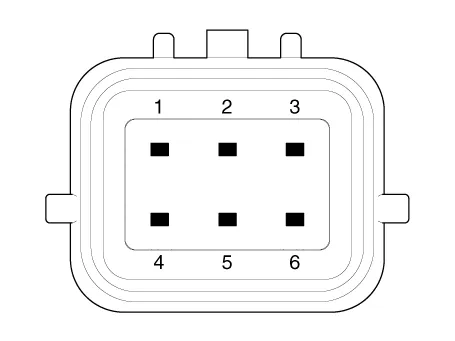

| Terminal function |

|

Pin No |

Description |

|

1 |

IGN1 |

|

2 |

IBU |

|

3 |

- |

|

4 |

B+ |

|

5 |

Stop lmap |

|

6 |

Ground |

Troubleshooting

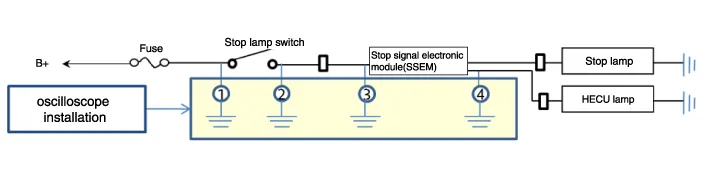

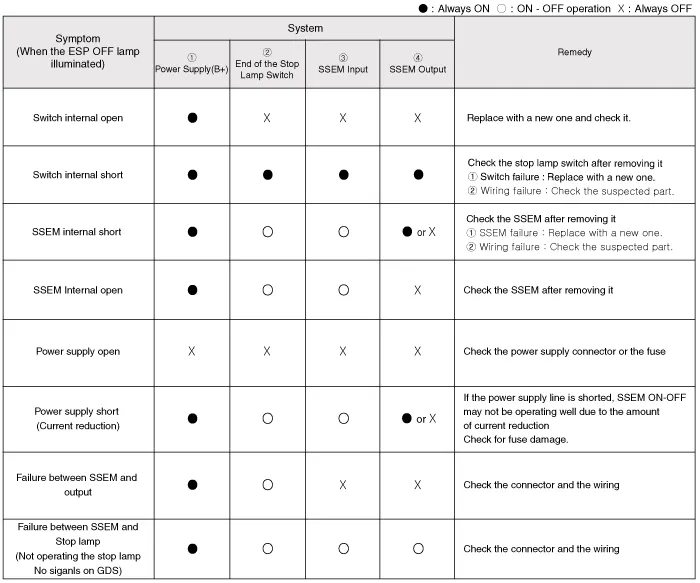

| Troubleshooting |

| 1. |

Part diagnosis

|

| 2. |

Symptom diagnosis

|

| 3. |

Stop lamp switch system diagnosis

SSEM : Stop Signal Electronic Module |

| 4. |

Refer to DTC guide when the related DTC codes are displayed. |

Repair procedures

| Removal |

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable. |

| 2. |

Remove the crash pad lower panel. (Refer to Body - "Crash Pad Lower Panel") |

| 3. |

Remove the knee airbag. (Refer to Restraint - "Knee airbag (KAB) module") |

| 4. |

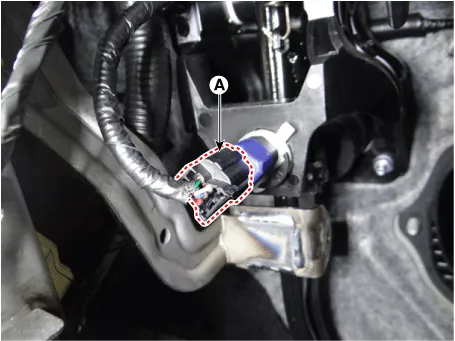

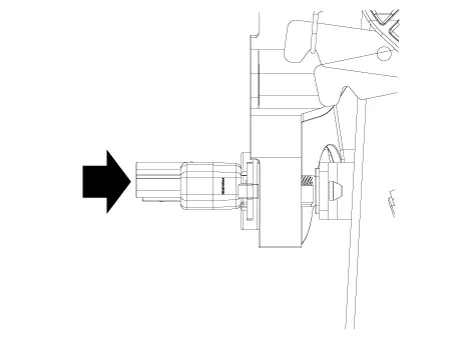

Disconnect the brake lamp switch connector (A).

|

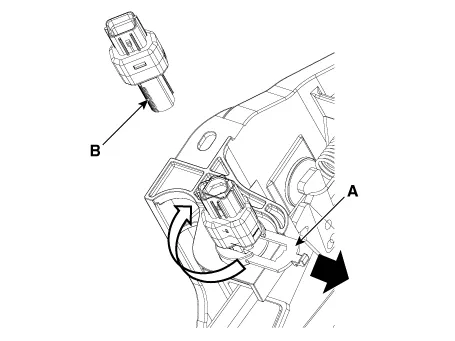

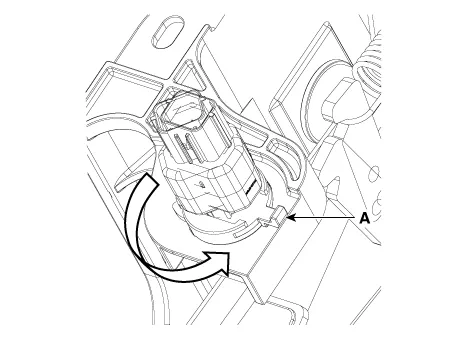

| 5. |

Pull the locking plate (A) as indicated by the arrow and then turn brake switch (B) 45° clockwise and remove it.

|

| 6. |

Inspect a removed stop lamp switch along the below procedures.

|

| Installation |

| 1. |

Fix the brake pedal arm and insert fully the brake switch so that the contact part is invisible.

|

| 2. |

After inserting, turn the brake switch 45° counterclockwise, and then assemble locking plate by pushing.

|

| 3. |

Confirm the gap between stop lamp switch and bracket.

|

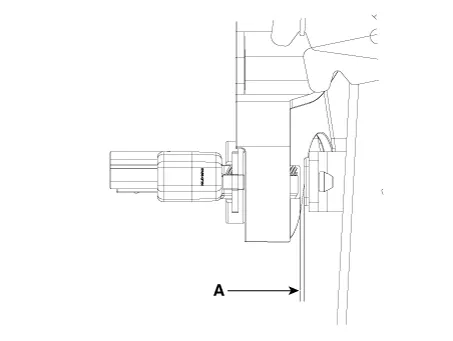

| 4. |

Install the stop lamp switch connector (A).

|

| Inspection |

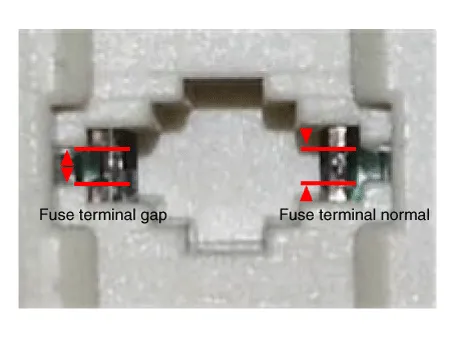

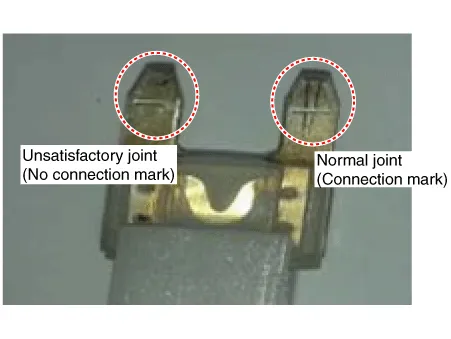

1. Fuse inspection

Mount the test fuse to the switch fuse and relay fuse part to confirm a normal joint fit.

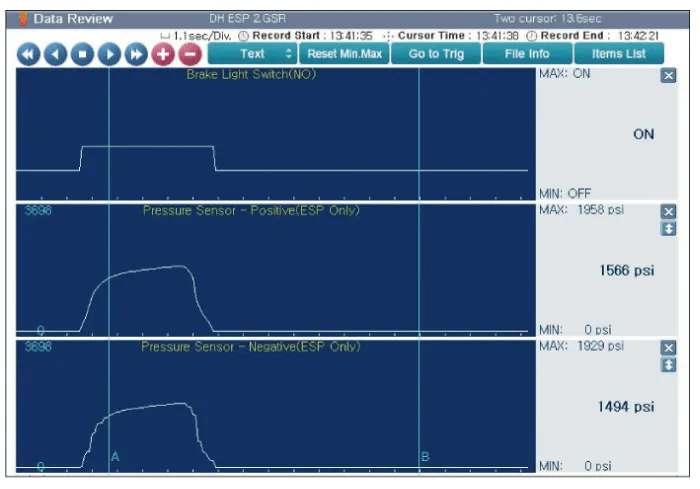

2. KDS Data Analysis

| 1. |

Analyze KDS data and check for any abnormality with the stop lamp switch.

|

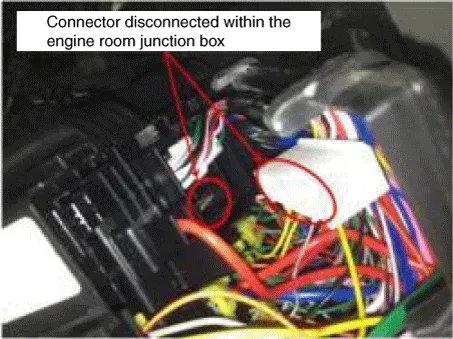

3. Inspection of connector by each part

Check for damage, terminal surge or incomplete connection in each connector.

[Engine room junction box]

[ABS/VDC control module]

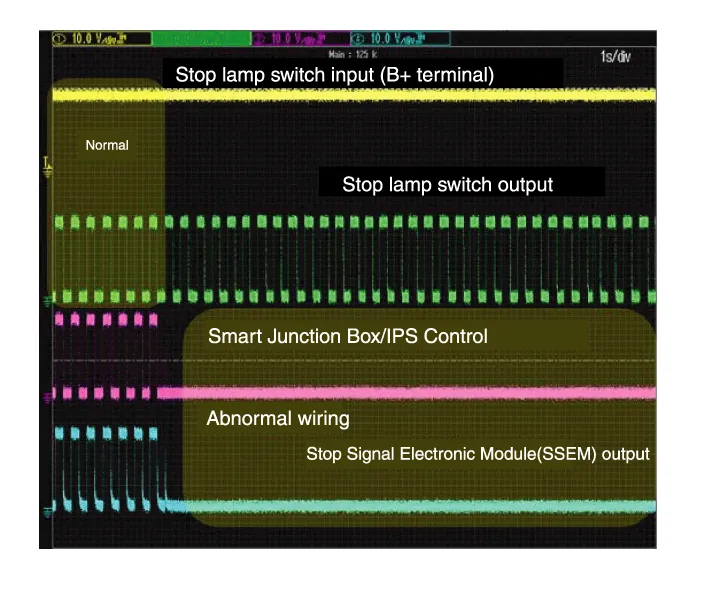

4. Inspect the stop lamp circuit

Connect probe to each terminal wire and confirm oscilloscope waveform.

[Stop lamp switch input/output]

[Oscilloscope waveform screen]

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: Power Window Motor

Components and components location Components [Safety Window Motor] [Standard Window Motor] Repair procedures Removal • When removing with a flat-tip screwdriver or remover, wrap protective tape around the tools to prevent damage to components.Kia Stinger (CK) 2018-2023 Service Manual: Parking Distance Warning (PDW) Sensor

Components and components location Components Repair procedures Removal Parking Distance Warning-Forward (PDW-F) Sensor 1. Disconnect the negative (-) battery terminal. 2. Remove the front bumper assembly. (Refer to Body - "Front Bumper Assembly") 3.Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- New on site

- Most important about car