Kia Stinger CK: Brake System / Front Disc Brake

Components and components location

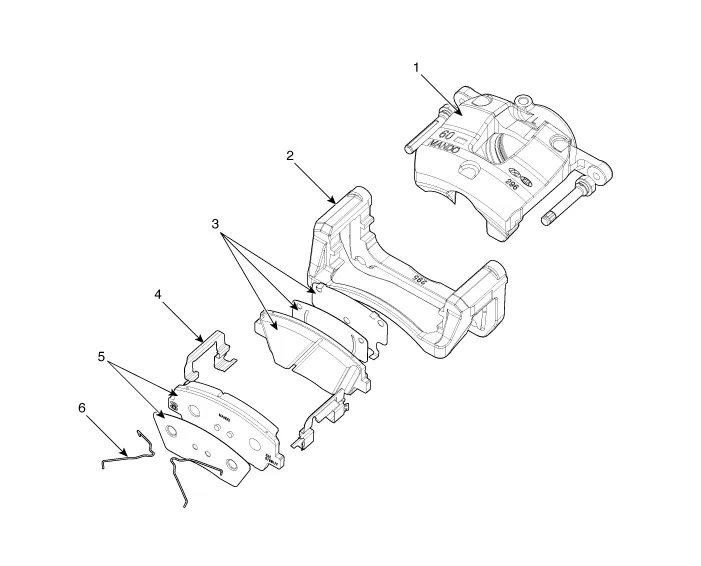

| Components |

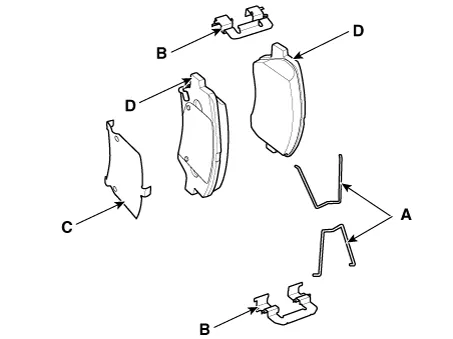

| [Standard] |

| 1. Caliper housing 2. Brake member 3. Brake pad assembly [IN] |

4. Retainer 5. Brake pad assembly [OUT] 6. Brake pad return spring |

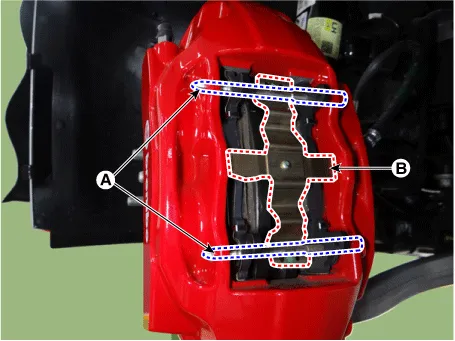

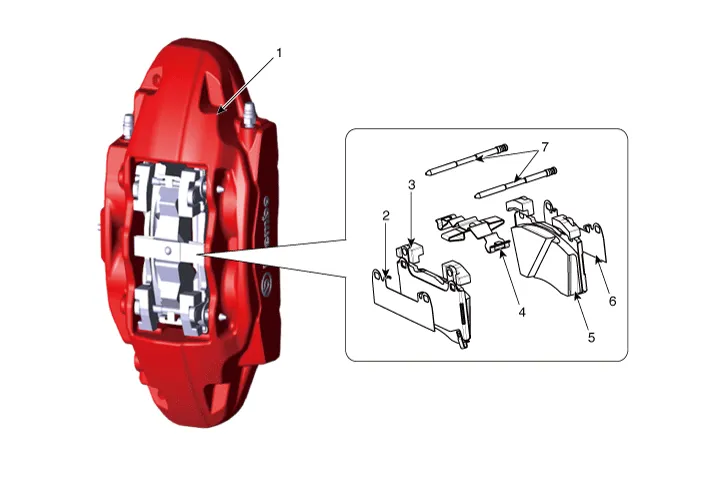

| [Brembo] |

| 1. Caliper housing 2. Brake pad cover 3. Brake pad 4. Retraction spring |

5. Brake pad 6. Brake pad cover 7. Guide pin |

Repair procedures

| Removal |

[Standard]

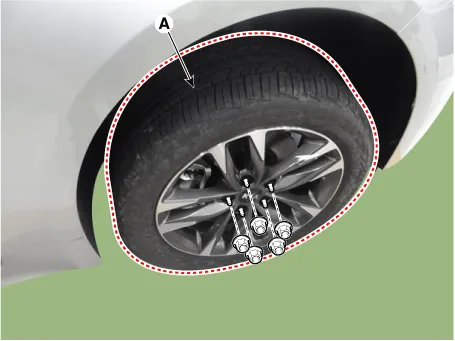

| 1. |

Remove wheel nuts, front wheel and tire (A) from front hub.

|

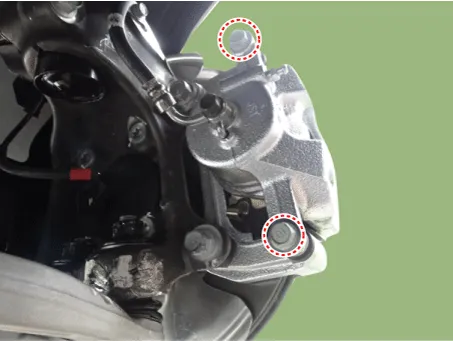

| 2. |

Loosen the brake caliper guide bolts and then remove the brake caliper.

|

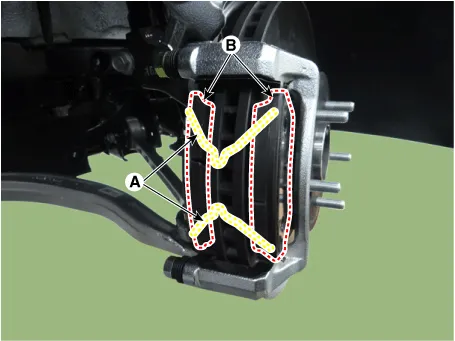

| 3. |

Remove the return spring (A), brake pad (B).

|

| 4. |

Loosen the brake member assembly bolts and then remove the brake member assembly.

|

| 5. |

Loosen the brake disc screw and then remove the brake disc.

|

| 6. |

Install in the reverse order of removal. |

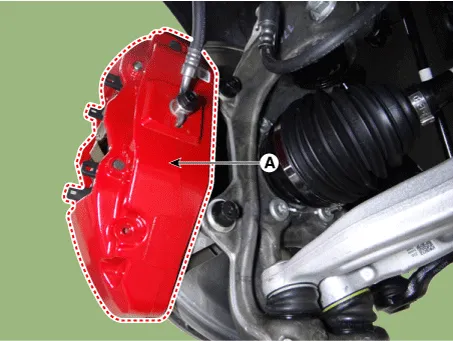

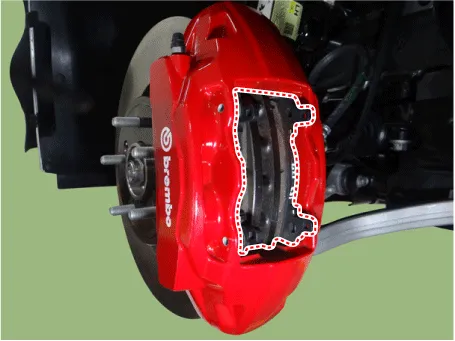

[Brembo]

| 1. |

Remove wheel nuts, front wheel and tire (A) from front hub.

|

| 2. |

Remove the brake caliper (A).

|

| 3. |

Loosen the brake disc screw and then remove the brake disc.

|

| 4. |

Install in the reverse order of removal. |

| Replacement |

| [Standard] |

Brake pad

| 1. |

Remove wheel nuts, front wheel and tire (A) from front hub.

|

| 2. |

Loosen the guide rod bolt and then pivot the caliper body up out of the way.

|

| 3. |

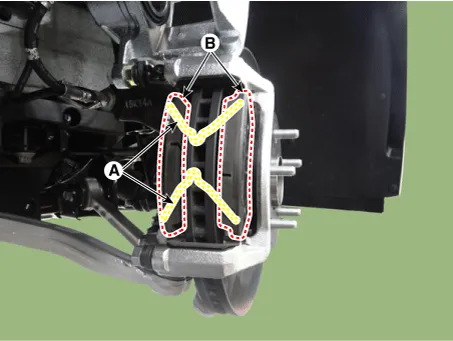

Remove the return spring (A), brake pad (B).

|

| 4. |

Install in the reverse order of removal. |

| 5. |

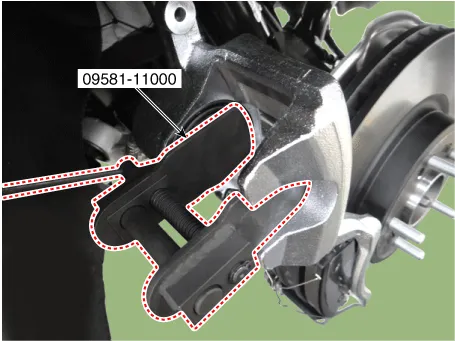

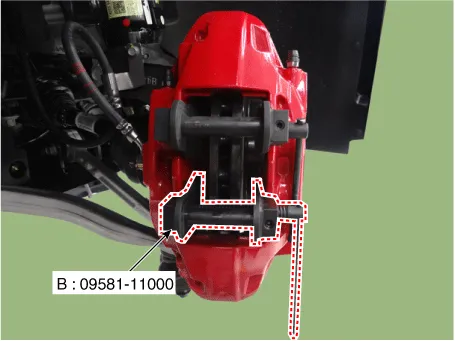

Use the SST (09581-11000) when installing the brake caliper assembly.

|

| 6. |

After installation, bleed the brake system. (Refer to Brake system - "Brake Bleeding Procedures") |

| [Brembo] |

Brake pad

| 1. |

Remove wheel nuts, front wheel and tire (A) from front hub.

|

| 2. |

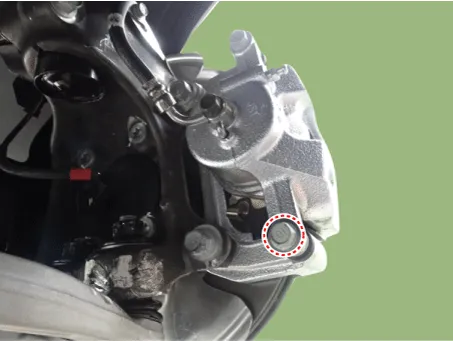

Push the guide pin (A) and then remove the retraction spring (B).

|

| 3. |

Remove the brake pad.

|

| 4. |

Install in the reverse order of removal. |

| 5. |

Use the SST (09581-11000) when installing the brake caliper assembly.

|

| 6. |

Use the SST (09581-11000) when installing the brake caliper assembly.

|

| 7. |

After installation, bleed the brake system. (Refer to Brake system - "Brake Bleeding Procedures") |

| Inspection |

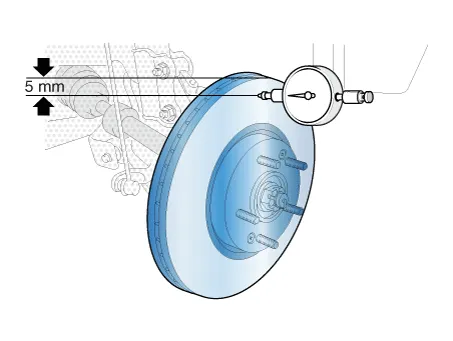

Front brake disc thickness check

| 1. |

Check the brake pads for wear and fade. |

| 2. |

Check the brake disc for damage and cracks. |

| 3. |

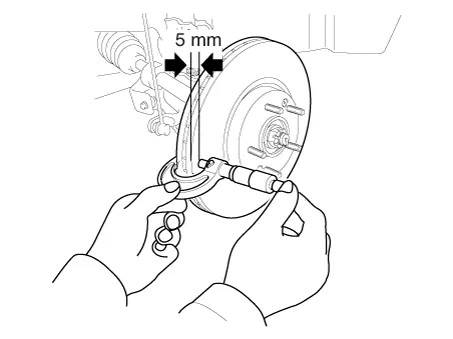

Remove all rust and contamination from the surface, and measure the disc thickness at 8 points, at least, at the same distance (5mm) apart from the brake disc outer circle.

|

| 4. |

If wear exceeds the limit, replace the discs and pad assembly left and right of the vehicle. |

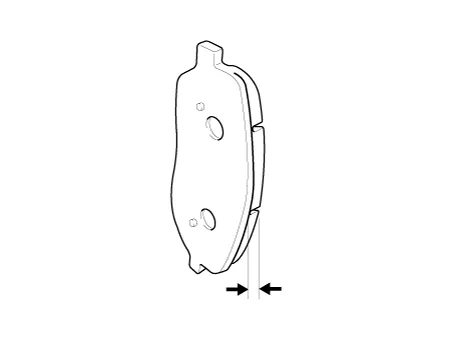

Front Brake Pad Check

| 1. |

Check the pad wear. Measure the pad thickness and replace it, if it is less than the specified value.

|

| 2. |

Check that grease is applied to sliding contact points and check the pad and backing metal for damage. |

Front brake disc runout check

| 1. |

Place a dial gauge about 5mm (0.2 in.) from the outer circumference of the brake disc, and measure the runout of the disc.

|

| 2. |

If the runout of the brake disc exceeds the limit specification, replace the disc, and then measure the runout again. |

| 3. |

If the runout does not exceed the limit specification, install the brake disc after turning it 180° and then check the brake disc again for runout. |

| 4. |

If the runout cannot be corrected by changing the position of the brake disc, replace the brake disc. |

Other information:

Kia Stinger (CK) 2018-2023 Service Manual: Parking Brake Assembly

Repair procedures Removal 1. Turn ignition switch OFF and disconnect the negative (-) battery cable. 2. Remove the crash pad lower panel. (Refer to Body - "Crash Pad Lower Panel") 3. Remove the knee airbag. (Refer to Restraint - "Knee airbag (KAB) module") 4.Kia Stinger (CK) 2018-2023 Service Manual: Fuel Filter (For Diesel engine only)

Repair procedures Removal 1. Switch "OFF" the ignition and disconnect the negative (-) battery terminal. 2. Remove the engine cover (A). 3. Disconnect the water sensor connector & fuel heater connector (A), fuel pressure sensor connector (B). 4.Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- New on site

- Most important about car