Kia Stinger CK: Body / Air Conditioner Refrigerant/Compressor

Repair procedures

| Refrigerant Recovery |

When removing HFC-134a (R-134a) from the air conditioning system, use only U.L.-listed service equipment certified to meet the requirements of SAE J2210.

|

If accidental system discharge occurs, ventilate the work area before resuming service.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.

| 1. |

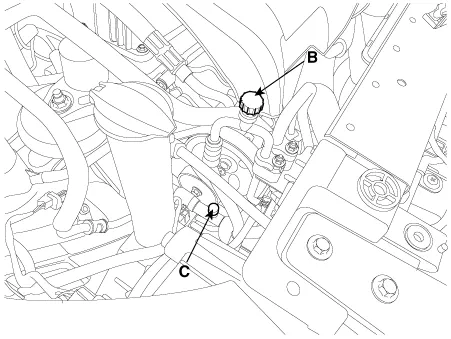

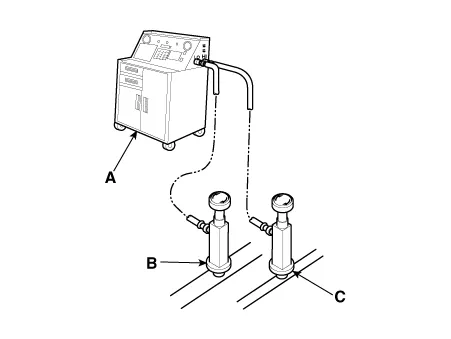

Connect an R-134a refrigerant Recovery/Recycling/Charging system (A) to the high-pressure service port (B) and the low-pressure service port (C) as shown according to the equipment manufacturer's instructions.

|

| 2. |

Measure the amount of refrigerant oil removed from the A/C system after the recovery process is completed. Be sure to install the same amount of new refrigerant oil back into the A/C system before charging. |

System Evacuation

When removing HFC-134a (R-134a) from the air conditioning system, use only U.L.-listed service equipment certified to meet the requirements of SAE J2210.

|

If accidental system discharge occurs, ventilate the work area before resume of service.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.

| 1. |

When an A/C system has been opened to the atmosphere, such as during installation or repair, it must be evacuated using a R-134a refrigerant Recovery/Recycling/Charging system. (If the system has been open for several days, the receiver/drier should be replaced, and the system should be evacuated for several hours.) |

| 2. |

Connect an R-134a refrigerant Recovery/Recycling/Charging system (A) to the high-pressure service port (B) and the low-pressure service port (C) as shown according to the equipment manufacturer's instructions.

|

| 3. |

If the low-pressure does not reach more than 93.3 kPa (700 mmHg, 27.6 in.Hg) in 10 minutes, there is probably a leak in the system. Partially charge the system, and check for leaks (see Refrigerant Leak Test.) |

| 4. |

Remove the low pressure valve from the low-pressure service port. |

System Charging

When removing HFC-134a (R-134a) from the air conditioning system, use only U.L.-listed service equipment certified to meet the requirements of SAE J2210.

|

If accidental system discharge occurs, ventilate the work area before resume of service.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.

| 1. |

Connect an R-134a refrigerant Recovery/Recycling/Charging system (A) to the high-pressure service port (B) as shown according to the equipment manufacturer's instructions.

|

| 2. |

Add the same amount of new refrigerant oil to the system that was removed during recovery. Use only specified refrigerant oil. Charge the system with [1100 ± 25g (38.8 ± 0.88oz.)] R-134a refrigerant. Do not overcharge the system as the compressor may be damaged. |

Refrigerant Leak Test

Always conduct a leak test with an electronic leak detector whenever leakage or refrigerant is suspected and when conducting service operations which are accompanied by disassembly or loosening connection fittings.

In order to use the leak detector properly, read the manual supplied by the manufacturer. |

If a gas leak is detected, proceed as follows:

| 1. |

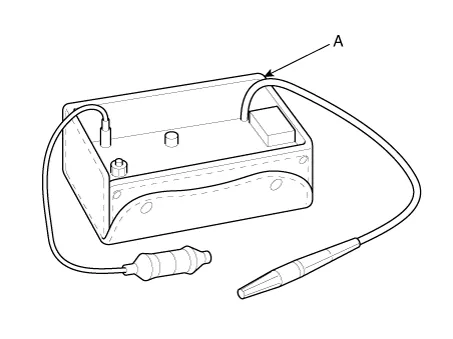

Check the torque on the connection fittings and, if too loose, tighten to the proper torque. Check for gas leakage with a leak detector (A). |

| 2. |

If leakage continues even after the fitting has been tightened, discharge the refrigerant from the system, disconnect the fittings, and check their seating faces for damage. Always replace, even if the damage is slight. |

| 3. |

Check the compressor oil and add oil if required. |

| 4. |

Charge the system and recheck for gas leaks. If no leaks are found, evacuate and charge the system again.

|

| Inspection |

| Compressor |

RPM check

| 1. |

Push the A/C control switch ON. |

| 2. |

Check the engine RPM.

|

| 3. |

During the compressor operation, RPM is as follows. [R 2.2 TCI]

[THETA 2.0 T-GDI]

[LAMBDA 3.3 T-GDI]

|

|||||||||||||||||||||||||||||||||||||||||||||

Sound check

| 1. |

Push the A/C control switch ON. |

| 2. |

Check the compressor from the engine room. |

| 3. |

During operation, the compressor makes a cracking sound.

|

Other information:

Components and components location Components 1. Manual control lever 2. Shift cable 3. Shift lever assembly 4. Knob Repair procedures Removal 1. Shift the gear to "N". 2. Loosen the nut (A) and remove the shift cable fixing clip (B).Repair procedures Removal Door Mirror Turn Signal Lamp 1. Disconnect the negative (-) battery terminal. 2. Remove the outside rear view mirror. (Refer to Body - "Outside Rear View Mirror") 3. Remove mirror (A) to the direction as shown in the picture using (-) screw driver.Categories

- Manuals Home

- Kia Stinger Owners Manual

- Kia Stinger Service Manual

- New on site

- Most important about car